Understanding Intelligent Valve Positioners: Digital Signal Transmission and Precise Pneumatic Actuator Adjustment

Intelligent valve positioners have transformed the way industrial valves are controlled. These sophisticated devices enable precise and continuous monitoring and adjustment of valve position, which in turn enhances the performance and efficiency of industrial processes. In 2025, advanced intelligent valve positioners are a foundational component of many industrial automation systems, particularly where high precision and reliability are critical requirements.

Valve positioners are essential for applications that require accurate control of fluid flow, such as chemical processing, oil and gas refining, and power generation. The primary function of a valve positioner is to convert a control signal from the automation system into precise movements of the valve stem, ensuring that the valve opens or closes to the required position. However, today’s intelligent valve positioners go beyond this basic functionality by using digital signal transmission and advanced technologies to provide real-time monitoring, diagnostics, and adjustment capabilities.

Testing Intelligent Valve Positioners: Designing a Robust Process

To ensure the effective deployment of intelligent valve positioners, a thorough testing process is essential. This begins with understanding the specific requirements of the application and designing a testing protocol that can validate the functionality, accuracy, and reliability of the positioner.

Testing Protocol Design

In the design phase, the critical components to test include the positioner’s signal processing, positional feedback, and valve actuation. For instance, to test the signal processing, one can use a programmable control system to generate a range of digital signals and observe the positioner’s response. The positional feedback can be verified by implementing a feedback mechanism, such as an encoder, to continually measure the valve’s position. Finally, the valve actuation can be tested by comparing the expected movement of the valve stem with the actual movement.

Choosing the Right Tools

When selecting testing tools, precision and accuracy are paramount. In 2025, various specialized instruments can be employed, such as signal generators, data acquisition systems, and test screws. Signal generators allow for the creation of precise control signals, while data acquisition systems enable the capture and analysis of real-time performance data. Test screws are used to simulate the load conditions the valve positioner will encounter in the field.

Verifying Results and Analyzing Data

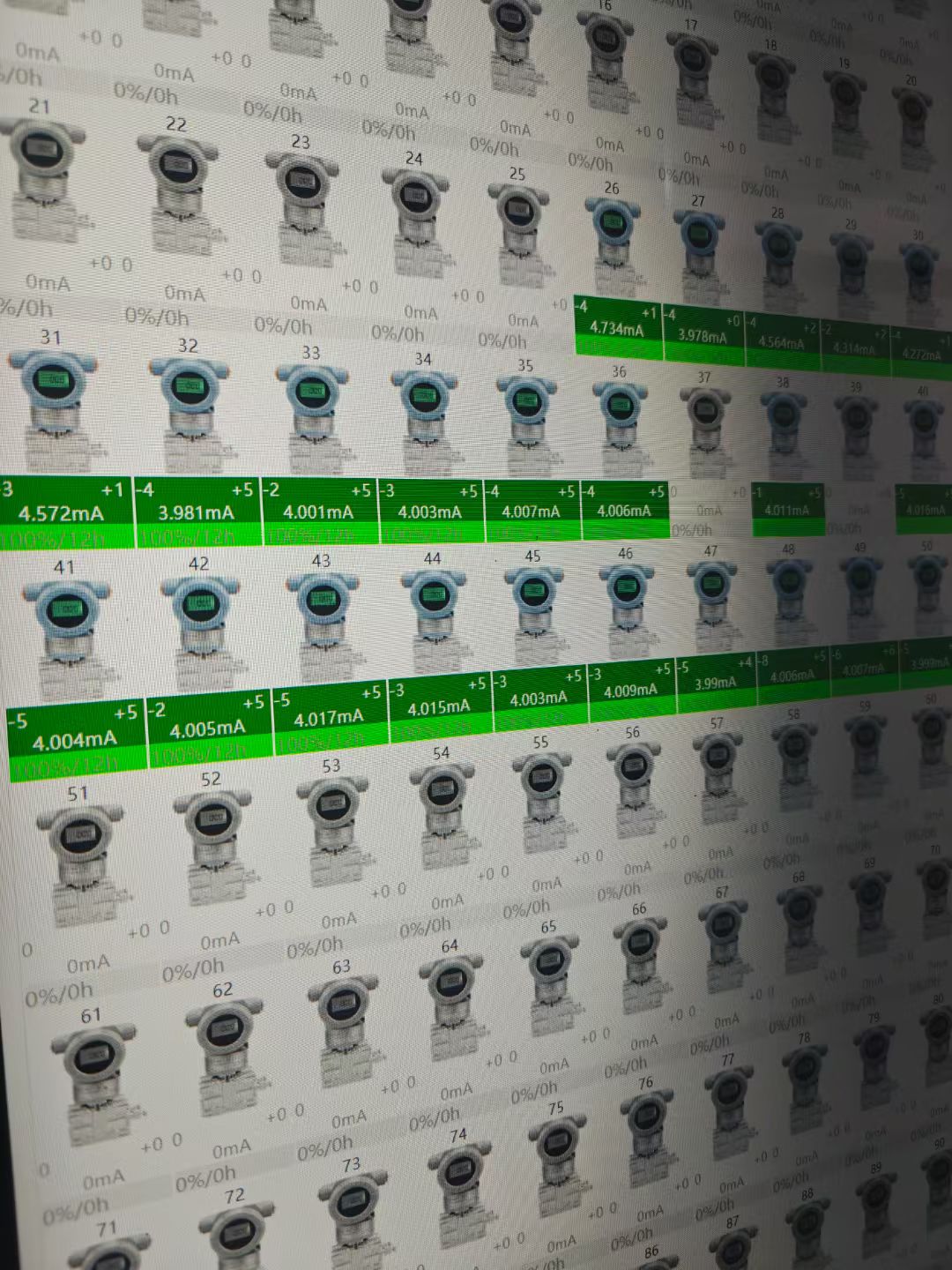

Once the tests are conducted, the next step is to analyze the results to ensure that the intelligent valve positioner meets the necessary standards. For example, the positional accuracy can be assessed by comparing the expected position with the actual position recorded by the feedback mechanism. The positioner’s response time can also be evaluated by measuring how quickly it adjusts the valve position in response to control signals.

One case study involves a petrochemical plant where a positioner was tested under varying conditions. The plant experienced frequent discrepancies between the control signal and the actual valve position. By using a digital signal generator and data acquisition system, it was determined that the issue was due to a delay in signal processing. Once this was identified, adjustments were made to optimize the algorithms, and the positioner’s performance improved significantly. This example highlights the importance of rigorous testing and data analysis in ensuring reliable operation.

Mastering the Art of Intelligent Valve Positioner Testing

To successfully test and optimize intelligent valve positioners, it’s crucial to combine theoretical knowledge with practical experience. Operators and engineers must be trained to understand the fundamentals of valve positioner operation and how to apply best practices in testing. Through hands-on experience and continuous education, they can achieve a deeper understanding of the intricacies involved in this process.

In summary, intelligent valve positioners are essential for modern industrial automation, and thorough testing using robust processes and tools is key to achieving optimal performance. By following expert guidelines and leveraging advanced technologies, engineers and operators can ensure that these devices meet the demanding requirements of today’s industrial environments.