Viscometer: Rotary Measurement, Real-Time Monitoring of Viscosity Changes During Lubricant Production Process

In the lubricant production industry, maintaining consistent product quality is paramount for both operational efficiency and customer satisfaction. Viscometers have become indispensable tools in the modern lubricant manufacturing process. They provide real-time monitoring of viscosity changes, helping manufacturers ensure that their products meet strict quality standards. As the demand for precise and reliable measurement techniques continues to grow, the use of viscometers has become more widespread. This article explores how rotary viscometers are used in the lubricant production process and highlights three key applications. It will also examine the competitive landscape and offer a glimpse into the future of this technology.

Industry Background

The lubricant industry has seen significant advancements in recent years, with a growing emphasis on ensuring top-tier performance across various applications, from automotive engines to industrial machinery. A rotary viscometer plays a vital role in this context by providing accurate measurements of viscosity under various conditions. The rotary viscometer works by rotating a spindle immersed in the sample at a constant speed while measuring the torque required to maintain this rotation. This method offers a direct and reliable way to determine viscosity, which is critical for maintaining consistency in lubricant quality.

Technical Driving Forces

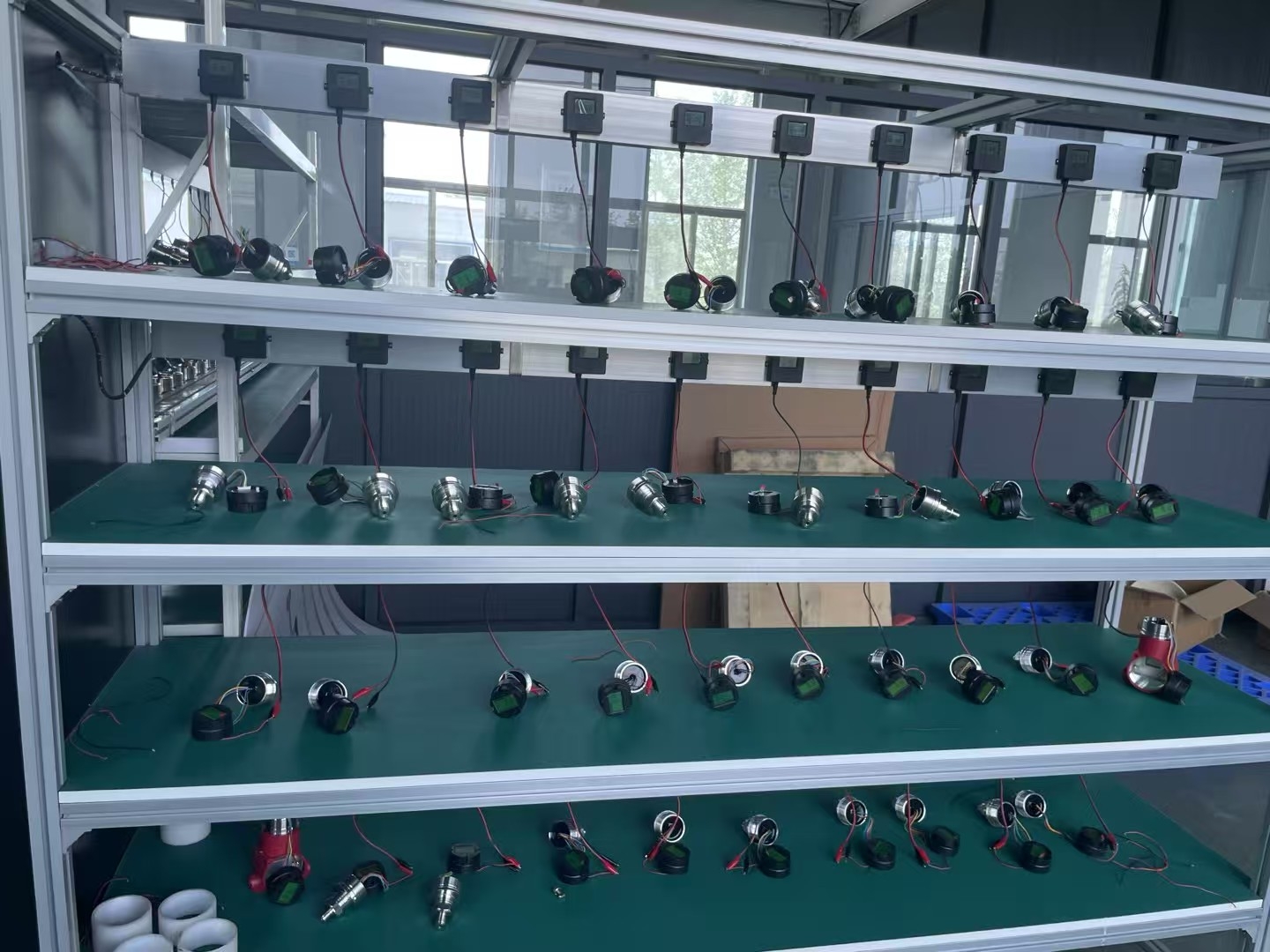

The development of rotary viscometers has been driven by the need for more precise and efficient measurements. Modern rotary viscometers are equipped with advanced sensors and software that enhance accuracy and speed of data acquisition. Digital sensors and high-speed microprocessors enable real-time monitoring and provide immediate feedback to operators. This level of precision is essential for maintaining consistent product quality and adhering to industry standards.

Applications

Quality Control During Production

One of the primary applications of rotary viscometers is quality control during the lubricant production process. Manufacturers use these devices to monitor viscosity parameters at critical stages, ensuring that the final product meets the required specifications. By integrating viscometers into the production line, companies can catch deviations early and make adjustments to maintain consistency.

R&D and Development

In the research and development phase, rotary viscometers are invaluable for assessing the performance of new lubricant formulations. These devices allow developers to test different compositions under various conditions, providing valuable insights into the viscosity behavior of potential new products. This information is crucial for optimizing formulations and ensuring they meet the desired performance criteria.

Field Testing

Field testing is another critical application of rotary viscometers. Once a lubricant is deployed in the field, it may encounter different temperatures and loads, which can affect its viscosity. Rotary viscometers can be used to monitor these changes in real-time, providing valuable data for troubleshooting and ensuring that the lubricant continues to perform optimally under varying conditions.

Competing Landscape

While rotary viscometers are the gold standard in the industry, there are other types of viscometers, such as cup and bob viscometers, that are also used. Cup and bob viscometers operate by immersing a bob in a fluid-filled cup and measuring the change in fluid level as the bob rises due to fluctuating torque. Although they are less accurate and slower than rotary viscometers, they remain popular due to their simplicity and lower cost.

Several manufacturers dominate the market for rotary viscometers, including Brookfield, HAAKE, and Haake. These companies offer a range of viscometers tailored to different industries and applications. The competition in this space is characterized by a focus on innovation and technological advancement, with manufacturers constantly striving to improve accuracy, reliability, and user-friendliness.

Future Outlook

The future of rotary viscometers is bright as technological advancements continue to push the boundaries of precision and efficiency. Enhanced sensors and software will likely drive further improvements in data accuracy and processing speed. Integrating artificial intelligence (AI) and Internet of Things (IoT) capabilities could also revolutionize how data is analyzed and utilized. By connecting viscometers to broader industrial networks, manufacturers can gain deeper insights into the behavior of lubricants and optimize their processes in real-time.

In conclusion, rotary viscometers have become indispensable in the lubricant production process, offering real-time viscosity monitoring and quality control. Their applications extend beyond production to research and development, and even to field testing. As the industry continues to evolve, the demand for precise and reliable viscometers is likely to remain high, fostering ongoing technological innovation and better product performance.