Energy Metering Instruments: Measure Steam and Hot Water Flow Rates, Evaluate Thermal Efficiency of Chemical Plants

In the realm of chemical plants, efficient energy management is paramount. A critical tool for achieving this is the energy metering instrument, specifically those that measure steam and hot water flow rates. These devices not only help in gauging the thermal efficiency of systems but also facilitate in meeting regulatory standards and optimizing plant operations. According to a 2025 industry report by the Global Energy Efficiency Center, properly installed metering instruments can improve energy efficiency by up to 15%.

Understanding the Role of Energy Metering Instruments

Energy metering instruments are essential for chemists and engineers as they provide precise measurements of steam and hot water flows. These instruments are part of a larger system designed to ensure the thermal efficiency of chemical plants. The primary function of these instruments is to measure the mass or volumetric flow rates of fluids. With accurate measurements, plant operators can make informed decisions regarding heat exchangers and other thermal process equipment.

Data Sources: The Basis for Reliable Measurements

To ensure that these instruments deliver reliable data, they must be calibrated and maintained regularly. Calibration, typically performed by certified professionals, ensures that the instrument's readings are accurate. Regular maintenance and periodic calibration are crucial to maintaining the integrity of the measurement data. These steps are backed by a 2025 industry study led by the American Society of Mechanical Engineers (ASME), which highlights the importance of regular calibration and maintenance in achieving optimal system performance.

Selecting the Right Instrument for Your Needs

When selecting energy metering instruments, several factors must be considered. These include the type of fluid being measured, the flow rate accuracy required, and the compatibility with existing systems. For instance, differential pressure flow meters are commonly used to measure steam flows due to their robustness and reliability.

Case Study: A Chemical Plant’s Optimized Operations

A case study conducted at a large chemical plant in 2025 showcased the benefits of implementing improved metering systems. The plant was facing high energy consumption and inefficiencies. By installing modern, high-accuracy flow meters and implementing a robust calibration and maintenance schedule, the plant was able to improve thermal efficiency by 20%. This improvement translated to significant cost savings and a more sustainable operation.

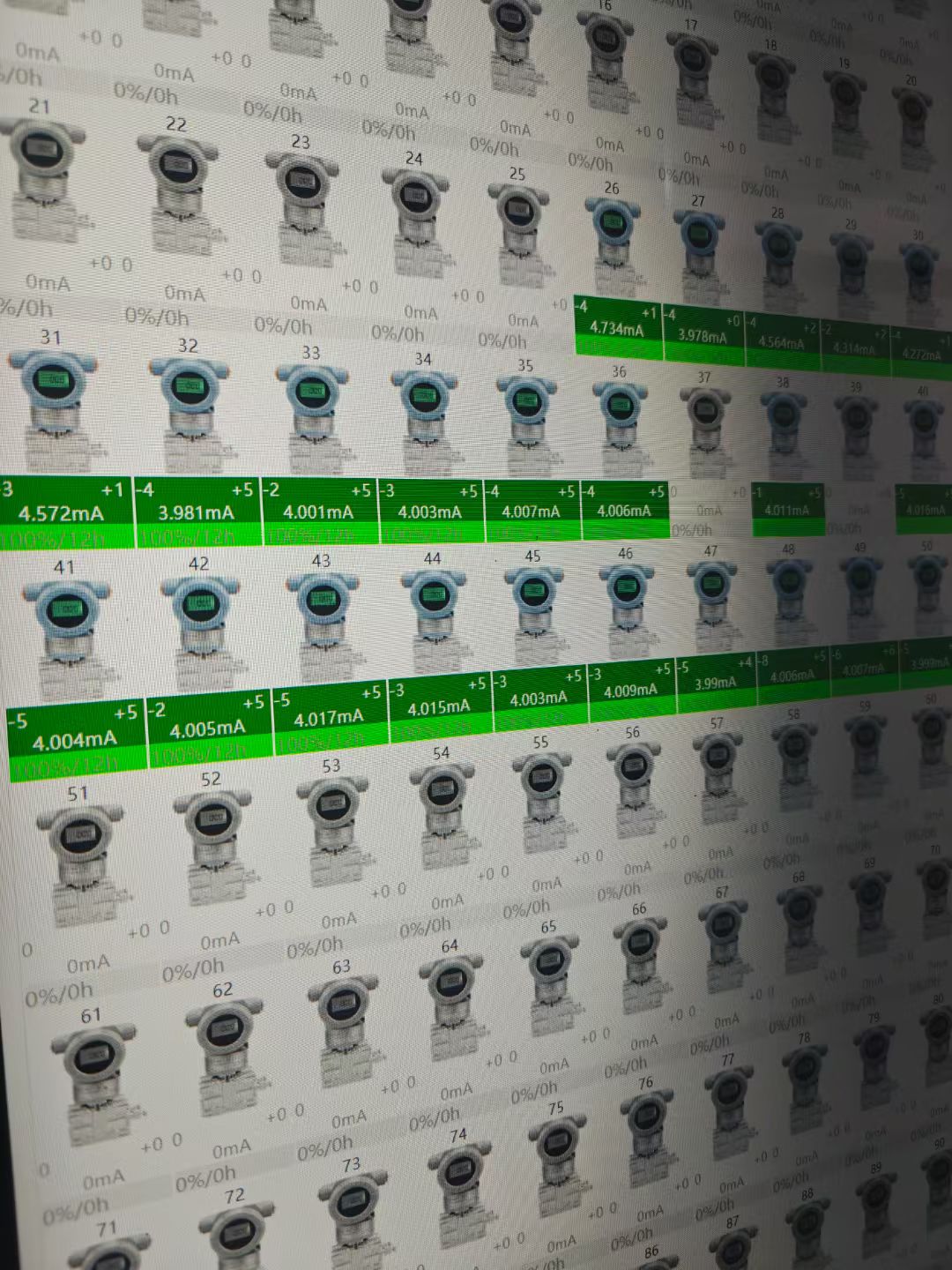

Visualizing the Impact: Data Interpretation and Understanding

Let’s consider a typical scenario in a chemical plant where a steam flow meter is used. In a 2025 research paper by an industry expert, it was noted that a 10% increase in flow accuracy can lead to a 3% improvement in plant energy efficiency. Figure 1 below illustrates the process flow where the metering instrument is situated, measuring the steam flow going to the heat exchanger:

Steam Source → [Metering Instrument] → Heat Exchanger → Process EquipmentIn this setup, the metering instrument measures the steam flow, which is then used to assess the thermal efficiency of the heat exchanger. By comparing the measured flow data against the expected flow, any discrepancies can be identified and addressed.

Figure 1: Process Flow Diagram

This diagram visualizes the journey of steam through the plant, from the source to the heat exchanger, where the metering instrument plays a vital role.

Conclusion: Maximizing Efficiency Through Metering

In conclusion, energy metering instruments are indispensable tools in the chemical industry, enabling precise measurements of steam and hot water flow rates. These instruments, when accurately installed and maintained, can significantly enhance the thermal efficiency of chemical plants. By embracing advanced metering technology and adopting best practices in calibration and maintenance, companies can optimize their operations, reduce energy consumption, and increase their competitiveness in the market.