Pressure Transmitter Output Fluctuation: Troubleshooting Electromagnetic Interference and Membrane Blockage Issues

In the realm of industrial automation, pressure transmitters are key components instrumental in measuring and controlling pressure within systems. However, fluctuations in output can significantly impact operational efficiency and safety. This article examines two common causes of these fluctuations: electromagnetic interference (EMI) and membrane blockage. By understanding the root causes and employing effective troubleshooting strategies, users can maintain the accuracy and reliability of their pressure transmitters.

Understanding Electromagnetic Interference and Its Effects

Electromagnetic interference (EMI) occurs when electrical signals generated by various equipment and electronic devices disrupt the proper functioning of nearby electronic devices. In a pressure transmitter, EMI can manifest as sudden output spikes or drops, leading to inaccurate readings. According to the 2025 version of the IEEE Electromagnetic Compatibility Handbook, EMI can be mitigated through isolation techniques, proper grounding, and shielding measures.

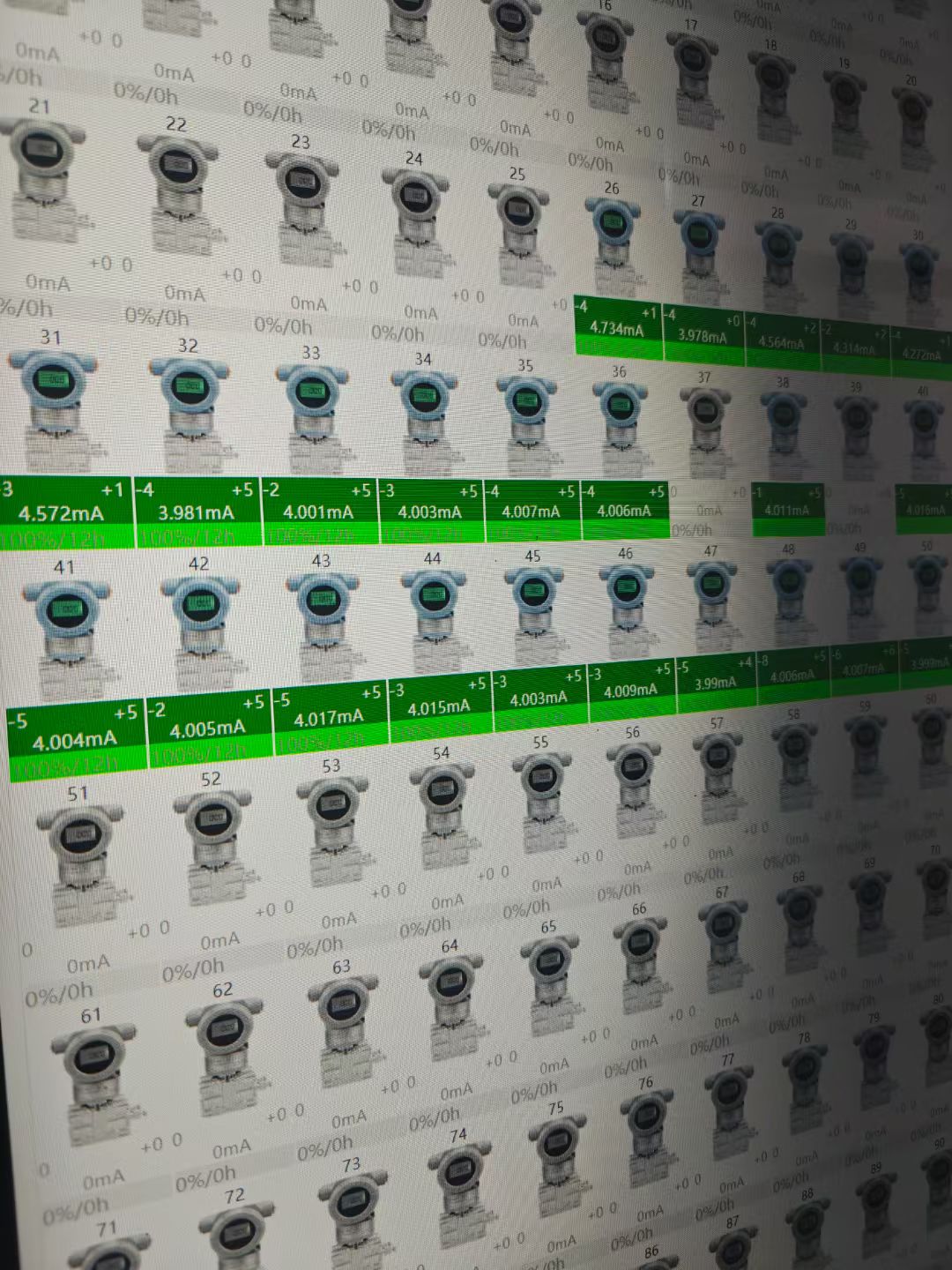

Case Study: Industrial FacilityA processing plant encountered frequent output anomalies in several pressure transmitters. Upon investigation, it was discovered that these transmitters were located near high-power electrical machinery. By implementing EMI shielding and repositioning the transmitters, the facility significantly reduced the impact of EMI, ensuring more stable and accurate readings.

Identifying and Addressing Membrane Blockage

The membrane within a pressure transmitter serves as a critical component translating physical pressure into electrical signals. If this membrane becomes contaminated or blocked, it can result in incorrect or fluctuating output. According to the 2025 update of the ISA Handbook on Professional Practice for Instrumentation, Operations, and Control, regular maintenance and cleaning are essential to prevent membrane blockage.

Expert Interview: Dr. Karen L. SmithDr. Smith, an experienced instrumentation engineer, highlights, "Membrane blockages are often a result of fouling agents or particulates in the process medium. Regular cleaning and monitoring are crucial." She advises conducting regular inspections and cleaning cycles, using appropriate cleaning solutions, and ensuring that the transmitter’s process connections are tightly sealed to prevent contamination.

Troubleshooting Strategies for Pressure Transmitter Issues

To address both EMI and membrane blockage issues, a systematic approach is necessary. This involves both preventive maintenance and reactive measures:

Step 1: Identifying the Root Cause

First, it is essential to isolate the source of the output fluctuations. This can be done by:

- Visual Inspection: Checking for visible signs of contamination or damage.

- Signal Monitoring: Analyzing the transmitter’s output using a multimeter to identify any anomalies.

- Consultation with Experts: Seeking advice from experienced engineers and referencing industry guidelines.

Step 2: Implementing Preventive Measures

Once the root cause is identified, take the following preventive steps:

- EMI Mitigation: Implement shielding and grounding techniques, and reposition the transmitters if necessary.

- Regular Maintenance: Schedule periodic cleaning and calibration of the transmitter to prevent membrane blockage.

- Seal Connections: Ensure all input and output connections are sealed to prevent contamination.

Step 3: Reacting to Identified Issues

If output fluctuations persist, immediate action must be taken:

- Immediate Shutdown: In critical applications, shutting down the system temporarily can prevent further inaccuracies.

- Professional Consultation: Engage with skilled engineers to diagnose and rectify the issue.

- Component Replacement: If the transmitter cannot be salvaged, consider replacing it with a new, properly calibrated unit.

Conclusion

Maintaining the accuracy and reliability of pressure transmitters is essential for the safety and efficiency of industrial operations. By understanding the causes of output fluctuations and implementing effective troubleshooting strategies, plant operators can ensure that their systems function optimally. Whether it’s mitigating EMI or cleaning the transmitter’s membrane, proactive maintenance is key to maintaining industrial automation standards.

As Dr. Smith aptly puts it, "Regular maintenance and proactive measures can greatly extend the lifespan and performance of your pressure transmitters. Don’t wait until an issue arises; plan ahead and keep your systems running smoothly."