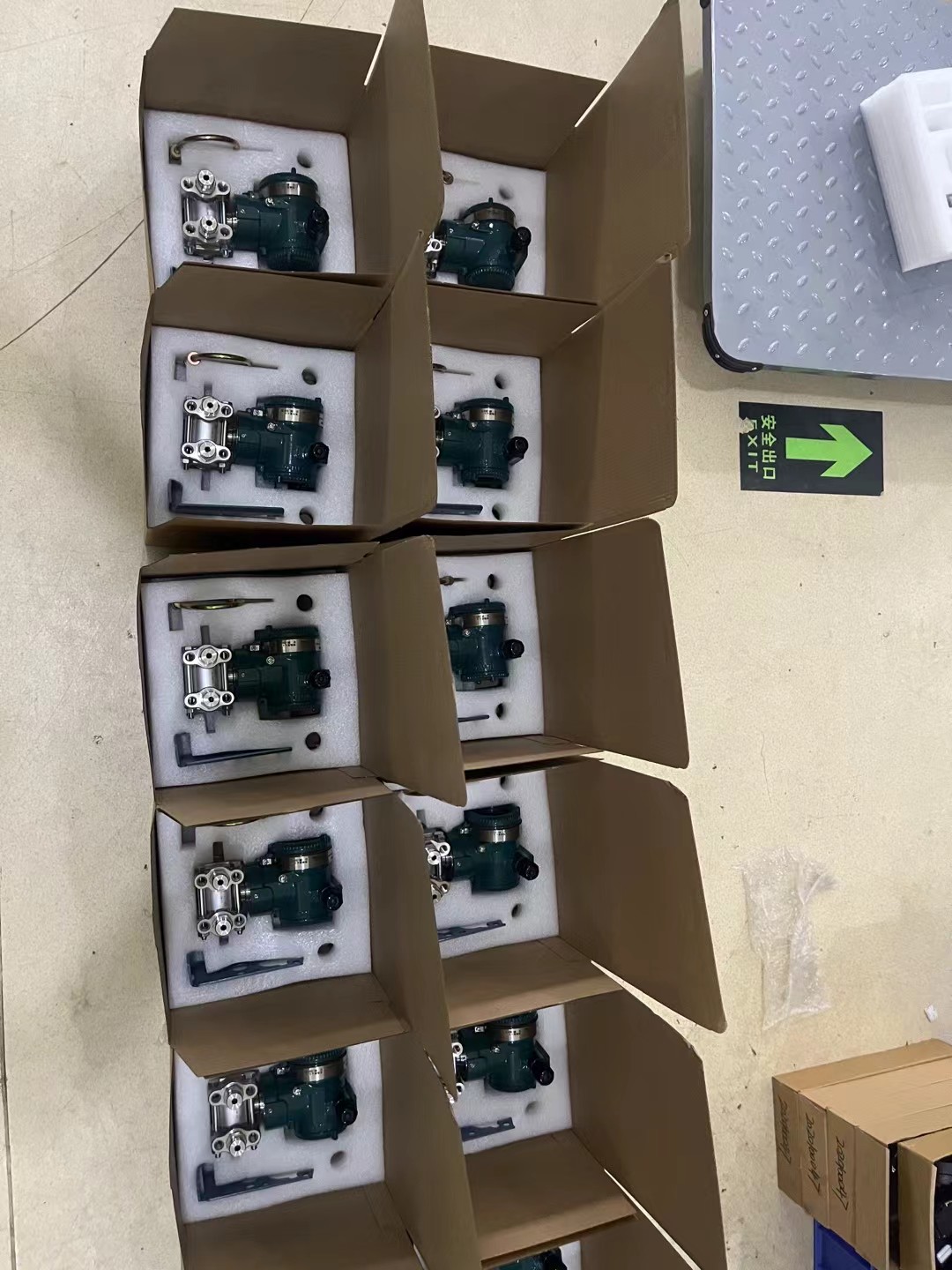

Instrument Valve Group: The Role of Three-Valve and Five-Valve Groups in the Installation of Differential Pressure Transmitters

In the realm of process industry, differential pressure transmitters play a crucial role in monitoring and regulating fluid flow, pressure, and other vital parameters. One of the most common challenges in their deployment is ensuring accurate and reliable readings while minimizing external disturbances. This is where the instrument valve group, specifically the three-valve and five-valve groups, come into play. These valve configurations are designed to enhance the performance and efficiency of differential pressure measurements. In this article, we explore the unique roles that three-valve and five-valve groups play in the installation and calibration of differential pressure transmitters.

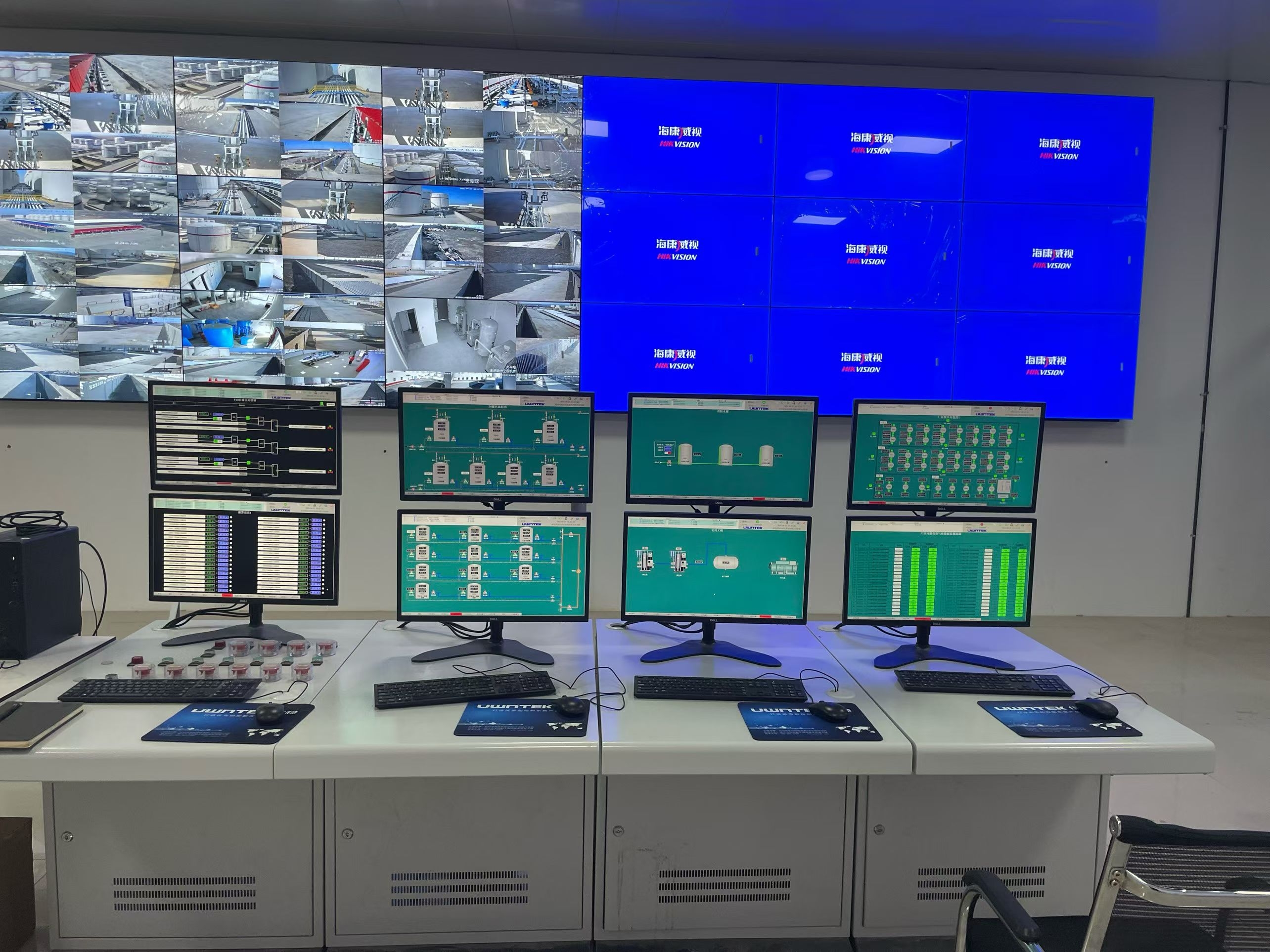

Technology-Driven Innovations in Metering and Control

The development of three-valve and five-valve groups has been driven by advancements in automation and smart instrumentation. These valves are equipped with digital communication capabilities, allowing for real-time data transmission and remote monitoring. In 2025, these innovations have significantly improved the accuracy and reliability of differential pressure measurements. Furthermore, they facilitate easier maintenance and calibration processes, which are essential for ensuring optimal performance in industrial applications.

Applications and Scenarios for Instrument Valve Groups

Instrument valve groups find extensive use in a variety of applications where precise fluid flow and pressure measurement are critical. Here are three key scenarios where the three-valve and five-valve groups are particularly useful:

- Process Control in Chemical Plants

In chemical plants, differential pressure transmitters measure the flow rates and pressures of various fluids. The three-valve and five-valve groups ensure that these measurements are not influenced by air bubbles, condensation, or entrained solids, leading to more accurate and reliable readings. This is crucial for maintaining the safety and efficiency of the production process.

- Water Treatment

The water treatment industry requires precise monitoring of turbidity, flow rates, and pressure changes in the treatment and distribution networks. Instrument valve groups help in isolating the differential pressure transmitter from the main flow path, allowing for continuous and uninterrupted measurements. This is particularly important in ensuring the water quality meets stringent regulatory standards.

- Petroleum Refineries

In petroleum refineries, differential pressure transmitters are used to measure the pressure drop across various stages of the refining process. The three-valve and five-valve groups ensure that these measurements are unaffected by the flow dynamics in the pipelines. This leads to more accurate assessment of the efficiency of each refining step, which is vital for optimizing the yield and reducing energy consumption.

Competitive Landscape and Market Dynamics

The market for instrument valve groups, particularly those designed for differential pressure transmitters, is competitive yet evolving. Major players like Aurora Technologies, Delta-M Volunteers, and Mahr Filter continue to innovate and develop advanced valve groups that integrate modern sensor technologies and communication protocols. These companies are focused on reducing downtime and improving the overall accuracy of the measurement systems.

In 2025, a notable trend in the market is the increasing demand for modular and programmable valve groups. These innovations allow for more flexible and scalable installation solutions, catering to the diverse needs of different industrial segments. Additionally, there is a growing emphasis on sustainability, with valve groups that incorporate energy-efficient designs and materials.

Future Outlook and Trends

Looking ahead, the future of instrument valve groups is bright, driven by several key trends:

- Integration of Artificial Intelligence (AI)

While AI is not directly used in the valve groups, the data they generate can be fed into AI-based predictive maintenance systems. This can help in identifying potential issues before they become critical, further enhancing the reliability of the measurement systems.

- Energy Efficiency

There is a strong focus on reducing the energy consumption of instrumentation systems. In 2025, we can expect to see more efficient designs and materials that minimize power usage without compromising on performance.

- Sustainability

Increased emphasis on sustainability is likely to drive the development of environmentally friendly materials and practices. This includes the use of recycled materials, energy-efficient manufacturing processes, and biodegradable coatings.

- ** dovetailing with Industry 4.0**

As part of the broader Industry 4.0 transformation, instrument valve groups will play a crucial role in connecting and optimizing industrial processes. This integration will enable real-time data analytics, predictive maintenance, and improved decision-making across the entire value chain.

In conclusion, the instrument valve groups, especially the three-valve and five-valve groups, are essential components in the installation and calibration of differential pressure transmitters. Their role in enhancing measurement accuracy and reliability cannot be overstated. As technology continues to evolve, these valve groups will increasingly leverage new innovations to meet the evolving demands of the industrial landscape.