From Mechanical to Intelligent: The Four Stages of Chemical Instrumentation Technology Evolution

In the 21st century, advancements in technology have fundamentally transformed the landscape of chemical instrumentation. From the mechanical era to the intelligent phase, the journey has been nothing short of fascinating. This evolution not only reflects a shift in technology but also signifies a profound impact on the way we understand and interact with chemical processes.

Stage 1: Mechanical Instruments (1970s-1980s)

In the early stages of chemical instrumentation, mechanical instruments were the backbone of laboratory work. These devices relied on manual input and mechanical feedback, providing a foundation for more precise measurements. Key examples from this era include the mechanical pH meter and quantitative analysis apparatus. The reliability and precision of these tools were crucial for early research and development.

Stage 2: Electronic Instruments (1980s-1990s)

As the technology advanced, electronic instruments started to emerge, marking the transition from purely mechanical to more integrated systems. By the 1980s and 1990s, electronic instruments began to dominate the landscape, offering enhanced accuracy and greater control over measurements. The introduction of electronic pH meters and digital chromatography equipment significantly improved the speed and reliability of data collection.

Stage 3: Intelligent Systems (2000s-2010s)

The early 2000s saw the rise of intelligent systems, characterized by the integration of software and data processing capabilities into instrumentation. This period marked a shift towards more sophisticated and adaptive tools. Intelligent instruments could perform complex analyses and provide real-time data feedback. Advances in automation, such as automated titration systems and intelligent process control devices, revolutionized chemical process management.

Stage 4: The Intelligent Phase (2025 and Beyond)

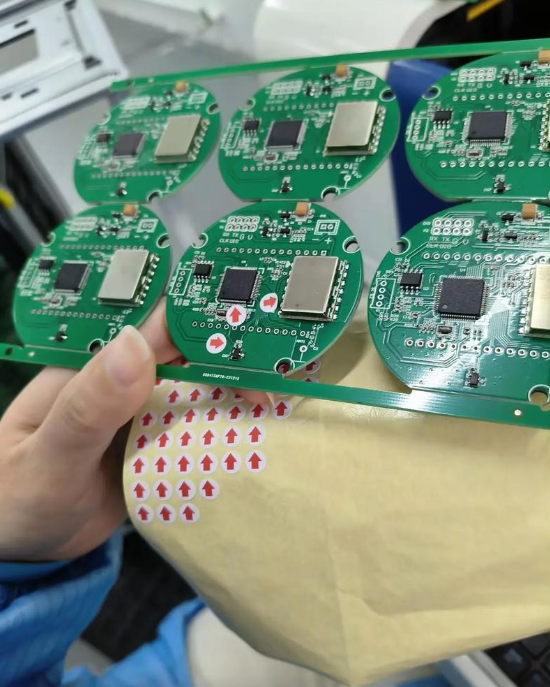

Entering the 21st century, the landscape of chemical instrumentation has shifted dramatically towards true intelligence. Today, instruments are not just tools for measurement but complete data management ecosystems. The seamless integration of artificial intelligence (AI), machine learning, and IoT (Internet of Things) technologies has led to the development of intelligent chemical analytical instruments. These instruments can interpret data, make predictions, and optimize processes without human intervention. Examples of this include AI-driven HPLC systems, ML-based spectroscopy devices, and cloud-connected reaction monitoring tools.

Analyzing the Advancements through Competitive Examples

Recent competitions and expert reviews have highlighted the improvements in chemical instrumentation technology. For instance, the Chemical Innovation Challenge of 2024 recognized instruments that could perform multiple tasks simultaneously and integrate real-time data analytics. One standout winner was the Smart Chemistry Suite, which integrated AI and machine learning to predict and optimize chemical reactions. Another notable example was the Advanced ChemProcess Monitoring System, which used IoT devices to collect and analyze data in real-time, offering unparalleled control and efficiency.

Innovative Features of Modern Instruments

Modern chemical instrumentation now features several cutting-edge tools and techniques. Data Analytics: Instruments can process vast amounts of data, providing insights and predictions through machine learning algorithms. IoT Integration: Devices can connect to a network of sensors, enhancing monitoring and control across multiple locations. AI-driven Optimization: Algorithms can adjust processes and parameters in real-time, significantly improving efficiency and yield.

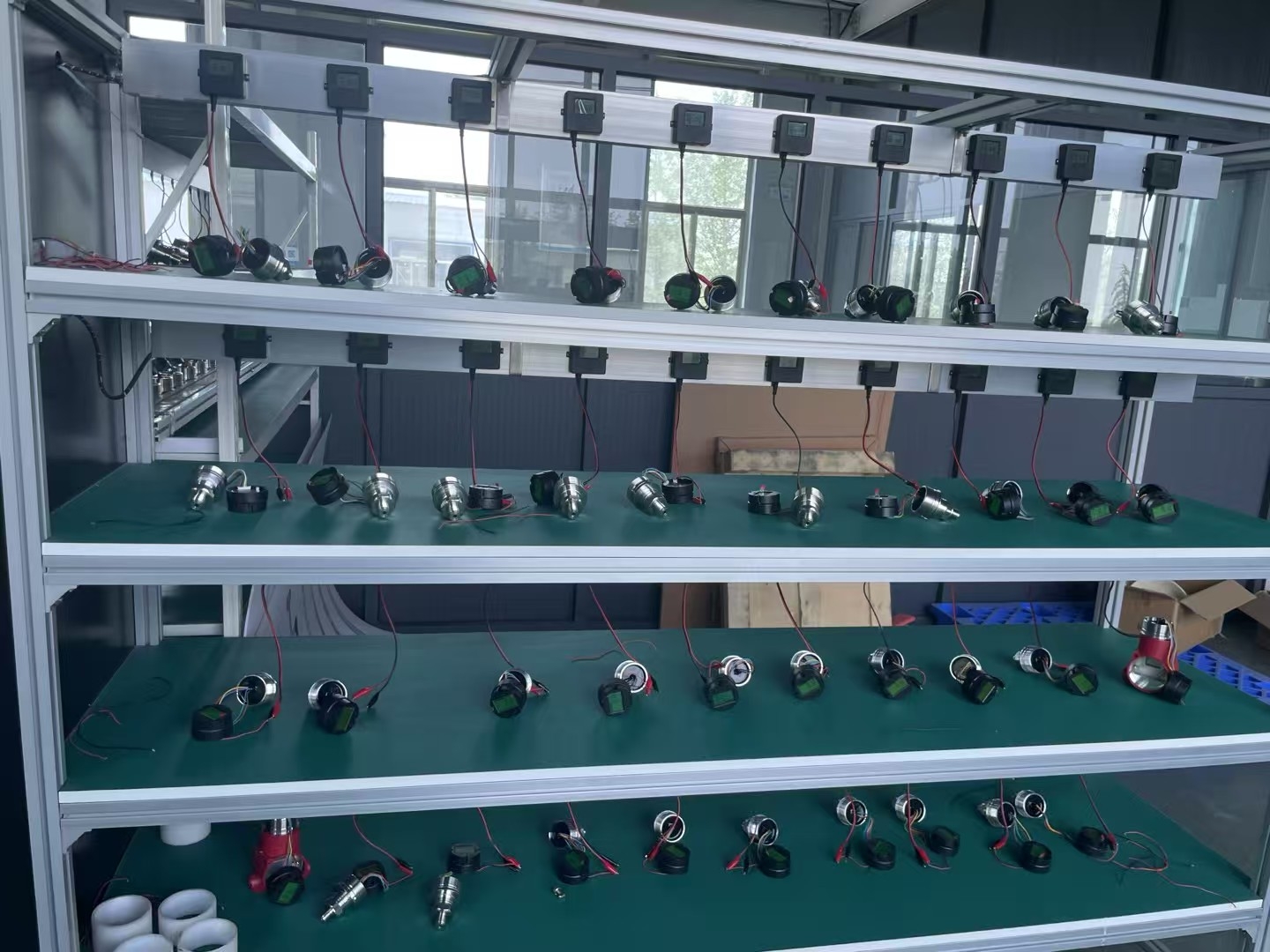

Methods and Implementation Strategies

To achieve these advancements, manufacturers and researchers have adopted several key strategies. Collaborative Research: Universities and industry partners work together to develop new technologies. Cross-disciplinary Teams: Combining expertise from chemistry, engineering, computer science, and AI creates innovative solutions. Phased Development: Gradually incorporating new technologies into existing instruments, allowing for continuous improvement.

Sharing Experiences to Guide Participation

Based on the experiences of leading scientists and engineers, participation in relevant competitions and conferences can be highly beneficial. Engaging with industry leaders and experts provides invaluable insights and networking opportunities. Additionally, continuous education and training in AI, machine learning, and data analytics are essential for staying ahead in this field. By fostering a culture of innovation and collaboration, the future of chemical instrumentation technology is bright and promising.

In conclusion, the evolution of chemical instrumentation from mechanical to intelligent phases represents a significant leap in technology. It underscores the importance of ongoing research and development, as well as the need for interdisciplinary collaboration. As we move forward into the 2025 era, the horizon for intelligent chemical instrumentation technology is vast, bringing immense promise for scientific advancement and industrial efficiency.