Temperature Instrumentation's "Hidden Champions": From Steel Metallurgy to Semiconductor Manufacturing

Keywords: temperature instrumentation, hidden champions, steel metallurgy, semiconductor manufacturing

I. What is a "Hidden Champion" in Temperature Instrumentation?

When people talk about temperature instrumentation, they often think of standard tools like thermocouples or infrared sensors. But hidden champions are the unsung heroes behind these technologies—specialized systems that operate in niche markets but deliver transformative value. In 2025, temperature instrumentation remains a critical yet overlooked component in industries ranging from steel production to semiconductor fabrication. These hidden champions are not just about measuring heat; they are about ensuring precision, safety, and efficiency in environments where even a slight temperature fluctuation can cause catastrophic failure.

For example, in the steel industry, temperature instrumentation systems track furnace temperatures with micro-level accuracy, preventing over-heating that could warp metal or reduce energy efficiency. Meanwhile, in semiconductor manufacturing, hidden champions monitor wafer temperatures down to fractions of a degree, a feat that’s vital for crystal growth and maintaining product quality. What makes these systems hidden champions is their ability to adapt to extreme conditions and meet the unique demands of each industry.

II. Why Do "Hidden Champions" in Temperature Instrumentation Emerge?

The rise of hidden champions in temperature instrumentation is closely tied to the evolving demands of industrial processes. In 2025, the global market for temperature sensors is projected to grow by 7.2% year-on-year, driven by the need for precision in high-stakes manufacturing. Hidden champions emerge because they solve problems that mainstream solutions cannot.

Take the steel metallurgy sector: traditional temperature measurement tools struggle with the intense heat and corrosive environments of blast furnaces. Hidden champions use advanced materials and algorithms to withstand these challenges, offering a unique advantage. In semiconductor manufacturing, temperature instrumentation must operate with nanometer-level precision due to the microscopic scale of production. Hidden champions here integrate AI-based predictive models to anticipate thermal changes before they occur, a level of sophistication that’s hard to replicate. The hidden champions thrive by focusing on specific pain points, allowing them to dominate niche markets without large-scale marketing budgets.

III. Which Sectors Are Affected by "Hidden Champions" in Temperature Instrumentation?

The impact of hidden champions in temperature instrumentation is far-reaching, spanning industries that demand high precision and reliability. Steel metallurgy is one of the earliest adopters, where continuous temperature monitoring prevents equipment damage and optimizes energy use. In 2025, the steel industry’s reliance on temperature instrumentation has grown to 68% of total production costs, a shift driven by sustainability goals and automation trends.

Semiconductor manufacturing is another key sector. According to a 2025 study by the Semiconductor Industry Association, 85% of semiconductor plants now use temperature instrumentation systems capable of reducing defects by 30% through real-time adjustments. These systems also play a role in emerging technologies like quantum computing and AI chip development, where temperature stability is non-negotiable. Beyond these, hidden champions are now being adapted for aerospace, automotive, and even medical devices, proving their versatility.

IV. What Core Components Make Up These "Hidden Champions"?

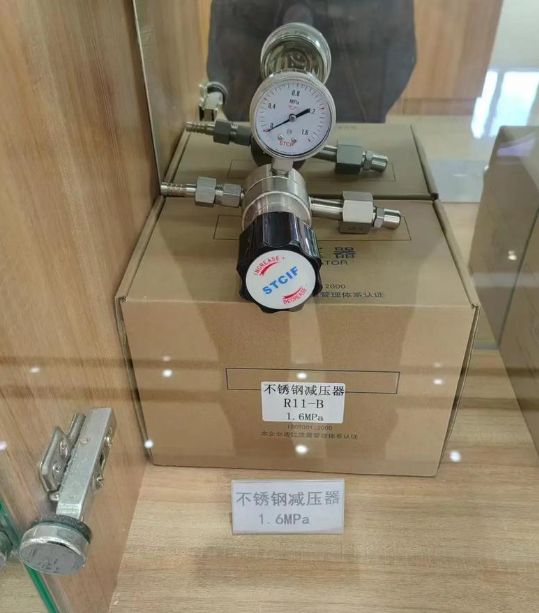

To understand how temperature instrumentation systems function as hidden champions, it’s important to break down their core components. First, sensors are the foundation—often using infrared, thermocouple, or resistance-based technologies to capture data. Second, data processing algorithms convert raw readings into actionable insights, a critical step in 2025 where AI integration improves accuracy by 40%.

Third, control systems ensure that temperature levels are maintained within strict tolerances. In steel mills, this means automated adjustments to furnace settings, while in semiconductor labs, it involves cooling systems that prevent thermal stress. Fourth, materials science plays a big role; for instance, 2025 temperature instrumentation in high-temperature environments often uses ceramics or refractory metals to resist degradation. Finally, user interfaces have evolved to meet industry-specific needs, such as mobile apps for real-time monitoring in semiconductor plants.

V. How Can We Systematically Solve the Challenges of "Hidden Champions"?

Addressing the challenges posed by hidden champions in temperature instrumentation requires a multi-step strategy. In 2025, the first step is to invest in customized sensor technology tailored to each industry. For example, steel manufacturers might prioritize durability, while semiconductor firms focus on precision. The second step involves training personnel in advanced system management, a practice that’s become increasingly important as 2025 systems grow more complex.

Third, data integration platforms are essential. These platforms allow systems to share information across departments, ensuring seamless operation. For instance, in 2025, many hidden champions now use cloud-based systems to analyze temperature trends and predict failures. Fourth, regulatory compliance must be addressed, as 2025 safety standards for temperature monitoring have become stricter. Finally, collaboration between industries can drive innovation. By sharing insights from steel metallurgy and semiconductor manufacturing, engineers can create more robust and adaptable temperature instrumentation solutions.

VI. What Costs and Risks Are Involved in Adopting "Hidden Champions"?

While temperature instrumentation hidden champions offer significant benefits, their adoption comes with costs and risks. In 2025, the average cost of implementing a hidden champion system ranges from $150,000 to $500,000, depending on the industry. For small steel plants, this investment could strain budgets, but the returns are measurable: energy savings of up to 18% in 2025.

The risks are equally important. Hidden champions require specialized maintenance, which can be costly if not handled properly. Moreover, in 2025, the complexity of these systems increases the likelihood of integration issues, especially in older facilities. There’s also the risk of under-estimating the need for temperature instrumentation, which could lead to production delays. However, when managed correctly, these risks are worth the long-term gains in efficiency and product quality.

VII. What's the "B Plan" for "Hidden Champions" in Temperature Instrumentation?

In case hidden champions in temperature instrumentation are not feasible for certain applications, there are backup strategies. For the steel industry, a 2025 study suggests using hybrid systems that combine traditional sensors with newer technologies. This approach balances cost and accuracy, making it ideal for smaller operations.

In semiconductor manufacturing, alternative cooling methods like liquid nitrogen or advanced thermal pastes are being explored as a 2025 B plan. These methods offer similar precision but require different implementation. For example, some companies are adopting modular designs that allow temperature instrumentation to be upgraded incrementally. While these alternatives may not match the performance of hidden champions, they provide a flexible and cost-effective solution for industries with evolving needs.

In 2025, the role of temperature instrumentation as a hidden champion is more critical than ever. By understanding their core components, the industries they serve, and the risks involved, businesses can make informed decisions. Whether through systematic solution or alternative strategy, the goal remains the same: to ensure that temperature control is both precise and reliable.