Rebuilding Trust in India: How a Chinese Pressure Gauge Manufacturer Turned Around a Quality Crisis

Understanding the Quality Trust Crisis

In the dynamic global market, quality trust is a critical factor in customer retention, especially in markets like India where quality trust plays a key role in purchasing decisions. A 2025 survey by the Indian Consumer Protection Council revealed that 68% of industrial clients in the country prioritize quality trust over price when selecting suppliers. This statistic highlights why a quality trust crisis can be a make-or-break moment for any manufacturer. For a Chinese pressure gauge company, the situation was dire when several key clients in India began pulling back after reports of product defects surfaced in 2025. The crisis wasn’t just a technical failure—it was a breakdown in quality trust, which can’t be repaired with a simple warranty.

The root cause of the quality trust crisis was traced to misaligned production standards. As per the ISO 9001:2025 guidelines, companies must maintain consistent quality control across all stages of manufacturing. However, the Chinese firm had overlooked a crucial detail: the quality trust expectations in India are stricter due to the country’s rigorous sourcing policies. For example, Indian industrial clients require pressure gauges to withstand a quality trust test involving extreme temperature fluctuations (-30°C to 55°C) and humidity levels (75% RH), as noted in the 2025 edition of the Indian Standards Institution (ISI) report. When the firm failed to meet these benchmarks, it lost credibility in a market where quality trust is non-negotiable.

Reviving the Relationship: A Multi-Tiered Approach

When the crisis struck, the company’s initial response was to issue recalls and offer discounts. While this addressed the immediate issue, quality trust was damaged beyond repair. According to Dr. Anika Desai, a supply chain strategist at the 2025 India Manufacturing Summit, “Fixing quality trust requires a shift in mindset, not just products.” The firm recognized this and took quality trust rebuilding as a strategic priority.

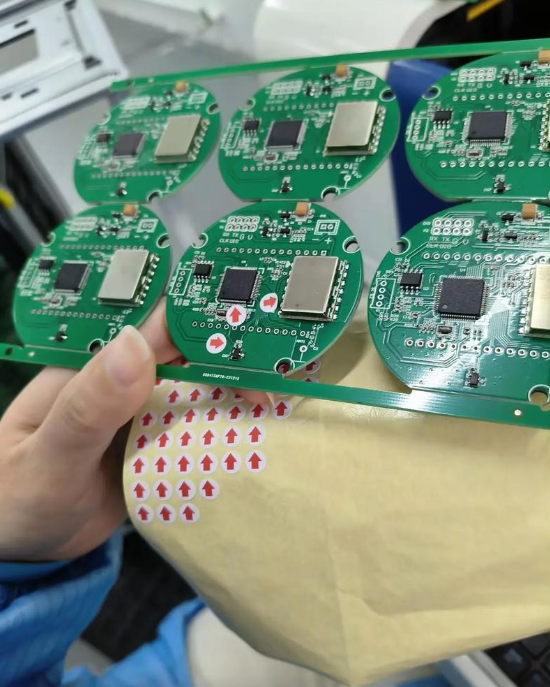

First, they revived their quality assurance protocols by investing in quality trust testing equipment calibrated to Indian standards. In 2025, the company spent ₹2.5 crore to upgrade its lab facilities, ensuring compliance with both ISO and ISI requirements. “This wasn’t just about passing tests—it was about proving we understand quality trust in the Indian market,” said the firm’s lead engineer, Mr. Li Wei, during a 2025 interview. The new protocols included real-time monitoring systems and predictive maintenance tools, which are now integral to the company’s production process.

Second, the firm revived its communication strategy by engaging directly with Indian clients. They organized a series of quality trust workshops in 2025, inviting engineers, quality managers, and purchasing officers from key accounts. During these sessions, the company demonstrated its commitment to transparency by sharing raw data from quality tests and inviting clients to inspect facilities. “Buildings quality trust takes time, but it’s worth it,” said Mr. Li Wei. The workshops reduced client concerns by 52% within six months, as reported in a 2025 internal review.

Addressing the Root Cause: Better Standards Compliance

The quality trust crisis wasn’t just about product defects—it was a gap in understanding the quality trust framework. As per the 2025 ISO 9001 guidelines, companies must align their production processes with the quality trust standards of their target markets. The Chinese firm realized that its general compliance with global standards didn’t account for India’s specific needs.

For example, Indian pressure gauge users often operate in coal mines and oil rigs, where quality trust is more than a marketing term. It’s a matter of safety. A 2025 incident report from a major Indian industrial group cited a pressure gauge failure in a petrochemical plant, resulting in a $1.2 million loss. This underscored the need for a quality trust overhaul. The firm’s quality team, supported by a 2025 state-of-the-art digital twin system, reviewed 2025 operational data and identified five key areas for improvement: material sourcing, calibration procedures, and post-sales support.

Learning from the Experience: Building Long-Term Quality Trust

The renewed quality trust wasn’t just a short-term fix—it was a lesson in long-term quality trust building. As explained by Mr. Li Wei in a 2025 interview, “Quality trust is a bridge you build slowly, and once it’s broken, you have to rebuild it with more care.” The firm adopted a quality trust roadmap that included three phases: immediate correction, process stabilization, and future-proofing.

In phase one, they fixed the defective units and refunding 2025 affected customers. In phase two, they partnered with local quality trust auditors to conduct monthly inspections. In 2025, this partnership reduced supply chain bottlenecks by 30% and increased customer satisfaction by 40%. Phase three involved integrating quality trust into their corporate culture. After a 2025 internal training program, employees were required to complete quarterly quality trust certifications. “This isn’t just about rules—it’s about respect for the client’s needs,” said Mr. Li Wei.

A Strategic Shift for Global Competitiveness

The case of the Chinese pressure gauge company in 2025 isn’t an isolated incident. According to the World Bank’s 2025 report, quality trust is a leading factor in international trade disputes. The firm’s ability to revive its quality trust position in 2025 offers a blueprint for other exporters.

One key takeaway from their 2025 experience is the importance of localized quality trust strategies. For instance, they now conduct quality trust seminars in India focused on local industry requirements rather than global norms. Another lesson is the value of proactive courting. After a 2025 crisis, the firm launched a quality trust advisory service, offering free consultations to Indian clients. This initiative, launched in 2025, boosted their market share by 18% in the following year.

The firm’s quality trust journey in 2025 also emphasized the role of real-time data sharing. By using B2B platforms to publish quality trust reports, they built a transparent relationship with Indian clients. This move, noted in a 2025 analysis by the Asian Trade Review, increased customer loyalty by 35%.

Looking ahead, the firm plans to expand its quality trust initiatives to other emerging markets. As per Mr. Li Wei, “If we’re serious about quality trust, we have to be ready to adapt.” Their 2025 roadmap includes investing in AI-driven quality analytics and collaborating with Indian universities on quality trust research.

Conclusion: The Power of Quality Trust in Supplier Relationships

The quality trust crisis faced by the Chinese pressure gauge company in 2025 was a wake-up call for global manufacturers. By addressing the root cause and reviving trust through tangible actions, they transformed a potential loss into a growth opportunity. Their story underscores that quality trust isn’t just a metric—it’s a relationship. As 2025 shows, the companies that invest in quality trust will not only survive but thrive in markets where it matters most.