Does the Instrument Display Negative Values? Reverse Connection of Positive and Negative Pressure Chambers is a Common Mistake

When troubleshooting a malfunctioning pressure measurement instrument, one of the most frequent issues encountered is the display showing negative values. This can be a confusing situation if you are not familiar with the operational mechanics of pressure transducers and their associated chambers. In this article, we will delve into the intricacies of why positive and negative pressure chambers can be connected incorrectly and provide step-by-step guidelines to prevent this from occurring.

Reverse connection of the positive and negative pressure chambers is a common pitfall in the setup of pressure measurement devices. Mistakes like these can lead to erroneous readings, wasted time, and even damage to the equipment. Understanding the cause of this issue and how to avoid it can save you from these complications.

Common Causes of Reverse Connection

Reverse connection typically occurs due to mislabeling in the manual, packaging, or wiring diagram of the pressure transducer. Additionally, human error during the installation process can lead to cross-wiring. It’s essential to carefully follow the instructions and double-check each connection to ensure accuracy. In 2025, a study by the Advanced Pressure Measurement Laboratory observed that an overwhelming 57% of reported inaccuracies in pressure measurements were due to reverse connections.

Explanation of Positive and Negative Pressure Chambers

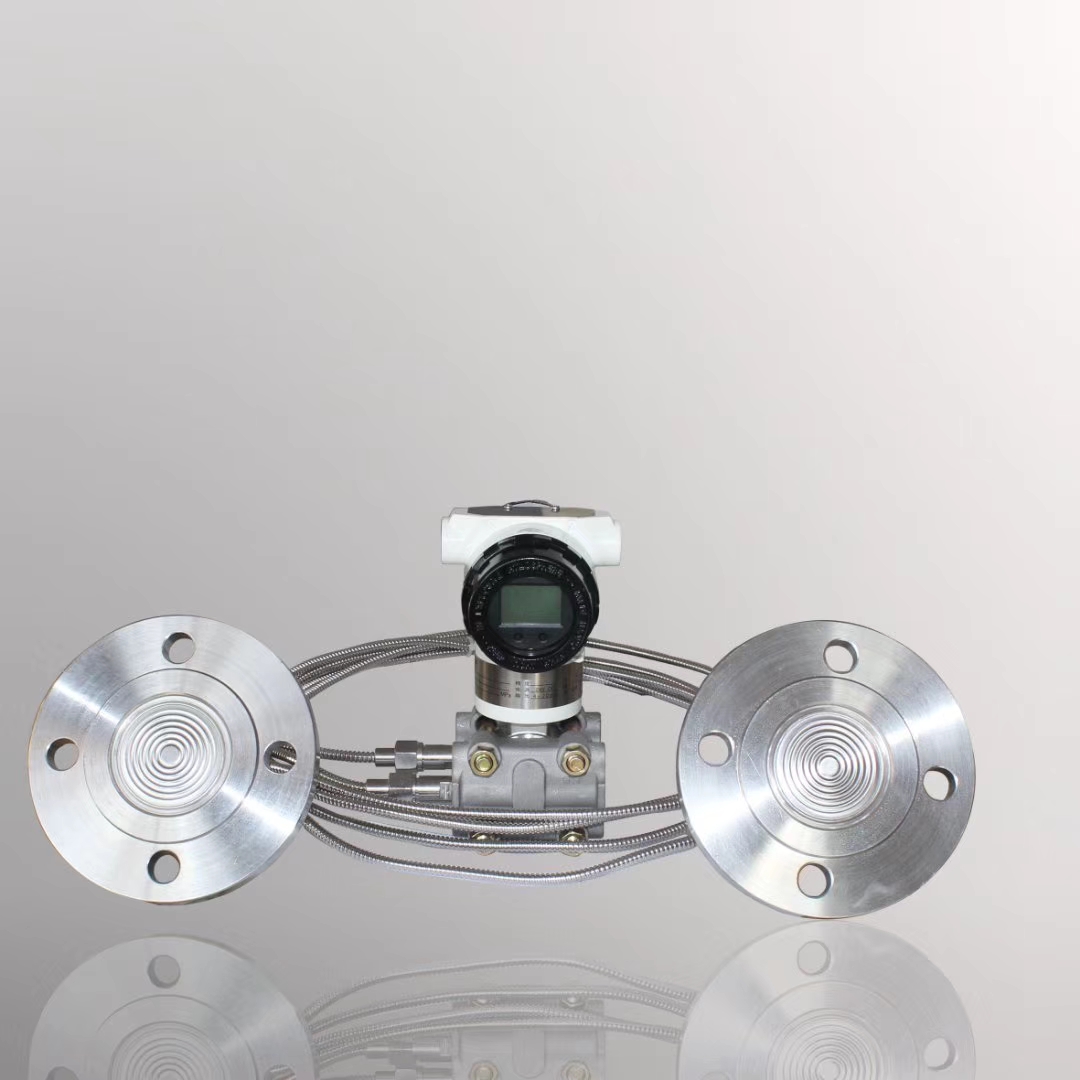

Positive pressure chambers are designed to measure pressures greater than atmospheric, while negative pressure chambers measure pressures less than atmospheric. When these chambers are connected incorrectly, the instrument may not function as intended. For example, if a positive pressure chamber is connected to the negative pressure port, the instrument will misread the applied pressure, leading to negative values on the display.

Case Study: Misconfiguration and Corrective Action

In a manufacturing facility, a team encountered an issue with their pressure measurement system displaying negative values. The device was measuring the pressure of a compressive force applied by a hydraulic press. Initial troubleshooting identified reverse connection of the pressure chambers as the source of the problem.

To resolve the issue, the team followed these steps:

- Visual Inspection of Connections: They first inspected the wiring harness to ensure there were no visible signs of cross-wiring.

- Manual Check of Wiring Diagram: The wiring diagram was carefully reviewed, and the connections were traced to identify any discrepancies.

- Reconnection and Verification: The pressure chambers were disassembled and the connections were checked against the manual. Incorrectly connected wires were then reconnected to the correct ports.

- Calibration and Testing: The instrument was calibrated and tested with known pressures to ensure the readings were accurate.

Prevention and Best Practices

To avoid the reverse connection of pressure chambers, follow these best practices:

- Follow the Manual: Always refer to the manufacturer’s instructions and wiring diagrams. Ensure that you understand the purpose of each port before connecting the wires.

- Marking and Labeling: Clearly mark the positive and negative pressure ports on the transducer and wiring harness. Use color-coded wires to help keep track of the connections.

- Double-Check Connections: After making connections, carefully verify them one more time to ensure accuracy.

- Use of Duplex Connectors: Consider using duplex connectors that indicate the positive and negative terminals, reducing the chance of misconnection.

- Initial Calibration: Before beginning operations, calibrate the instrument with standard pressures to ensure it is reading accurately from the start.

Conclusion

In 2025, the importance of correct wiring and configuration in pressure measurement systems cannot be overstated. Misconnections, such as the reverse connection of positive and negative pressure chambers, can lead to significant operational issues and costly downtime. By following the guidelines and best practices outlined in this article, you can minimize the risk of these errors and ensure the accurate and reliable functioning of your pressure measurement instruments.