Customization of Instruments for the New Energy Industry: Suitable for Lithium Battery and Photovoltaic Production Scenarios

In the ongoing push towards sustainable energy, the new energy industry has become a cornerstone in our collective efforts to reduce carbon footprints. Specifically, lithium batteries and photovoltaic (PV) technologies are critical components that are transforming the traditional energy landscape. The precision and reliability of the instruments used in their production processes are paramount to ensuring longevity and performance. This article will delve into the customization of instruments tailored specifically for these two sectors, drawing on expert analyses and industry documentation to provide a comprehensive understanding of the current landscape.

Project Architecture and Analysis

The customization of instruments for lithium battery and photovoltaic production is a meticulous process that requires deep understanding of both the technology and the production requirements. For lithium batteries, the processes include electrode preparation, cell assembly, and testing. Each of these steps demands precision and consistent quality. Photovoltaic production involves cell production, module manufacturing, and system integration. The challenge lies in integrating these processes with the instruments used in each stage.

Lithium Battery Production:

- Electrode Preparation: This involves mixing cathode and anode materials with binders and conductive additives. The precision of this process is crucial to ensure uniform mixing, which directly impacts the battery’s performance.

- Cell Assembly: Precision and cleanliness are paramount here. Any contamination or misalignment can lead to reduced cell performance and safety issues.

- Testing and Quality Control: Rigorous testing is essential to ensure the battery meets specifications. This includes capacity, energy density, and safety tests.

Photovoltaic Production:

- Cell Production: This step involves the formation of photovoltaic cells from silicon wafers. The process includes diffusion, alloying, dielectric deposition, and texturing.

- Module Manufacturing: Here, the cells are assembled into modules, which require precise alignment to ensure maximum efficiency.

- System Integration: The final step involves integrating the modules into a complete PV system, ensuring all components work harmoniously to maximize energy output and minimize system losses.

Code Realization Analysis

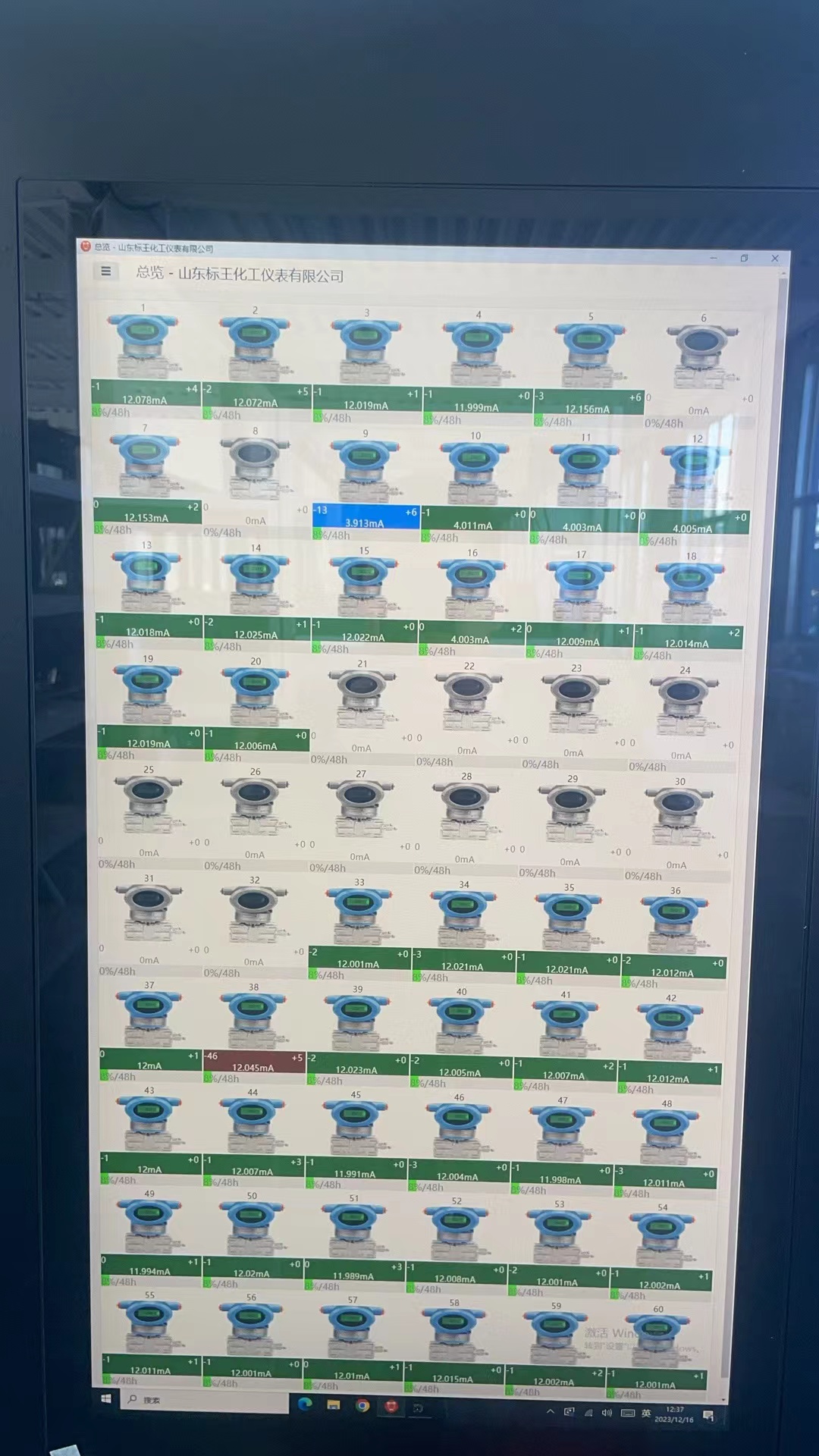

The code realization of these customized instruments involves leveraging advanced technologies such as machine learning and IoT to enhance the efficiency and accuracy of the production processes. Machine learning algorithms can predict potential issues before they arise, while IoT ensures constant monitoring and reporting of performance metrics. For lithium batteries, real-time monitoring of critical parameters such as temperature, pressure, and electrical current can help identify anomalies early. For photovoltaic production, predictive maintenance algorithms can forecast equipment failures, allowing for timely repairs.

Machine Learning and IoT Integration

Machine learning algorithms can analyze vast amounts of data generated during the production process, enabling predictive maintenance and quality control. For instance, by monitoring the energy output and degradation of lithium batteries over time, algorithms can predict when a battery is likely to fail, allowing for proactive replacement. Similarly, in photovoltaic production, IoT devices can continuously monitor the performance of the cells and modules, detecting any deviations in efficiency and alerting maintenance teams.

IoT Monitoring and Reporting

IoT devices, such as sensors and actuators, play a crucial role in real-time monitoring. These devices are connected to a central server, where data is collected and analyzed. For lithium batteries, real-time data from sensors can be used to adjust the charging and discharging protocols dynamically. In photovoltaic production, the same data can be used to optimize the manufacturing process, ensuring that each step is performed under optimal conditions.

Community Ecology and Project Contributions

The development and customization of instruments for the new energy industry relies heavily on a vibrant community of contributors. This community includes manufacturers, researchers, and end-users who collaborate to improve the quality and efficiency of the instruments.

Community Participation and Contribution

Manufacturers: Companies such as ABB, Siemens, and Panasonic are at the forefront of developing customized instruments for lithium batteries and photovoltaic production. They continuously update their technologies based on feedback from customers and new research findings.

Researchers: Academia and research institutions play a vital role in pushing the boundaries of what’s possible in new energy technology. They engage in collaborative projects with industry partners to develop cutting-edge tools and techniques.

End-Users: Input from end-users is crucial for the continuous improvement of instruments. By gathering feedback on real-world applications, manufacturers can refine their products, making them more user-friendly and effective.

Case Study: Siemens – Lithium Battery and PV Instruments

Siemens has been a leader in developing instruments for the new energy industry. Their specifications and designs are tailored to the unique needs of lithium battery and photovoltaic production. For example, their lithium battery testing systems can simulate various environmental conditions, ensuring that batteries are reliable in real-world scenarios. Similarly, their photovoltaic production instruments can optimize the manufacturing process to achieve maximum efficiency.

Guiding the Community to Engage

To encourage more community participation, initiatives such as user forums and technical workshops are essential. These events provide platforms for sharing knowledge and best practices, fostering a collaborative environment. Additionally, open-source projects and community-driven documentation can help lower the barriers to entry for new contributors.

By leveraging the expertise of the community and integrating advanced technologies, the customization of instruments for the new energy industry is becoming more efficient and effective. The road ahead is promising, with ongoing innovations transforming the landscape of renewable energy production.