Top 10 Diagnostic Methods for Instrument Faults: Essential for Maintenance Technicians!

In today’s industrial and technical landscape, the accuracy and reliability of instruments are of utmost importance. Faults in these instruments can lead to significant economic losses and even pose safety hazards. Maintenance technicians must be equipped with a robust set of diagnostic methods to accurately identify and resolve instrument faults. The following are essential diagnostic methods that are crucial for ensuring the continuous and efficient operation of instruments.

1. Analyze Instrument Readings

One of the foundational techniques in diagnosing instrument faults is to analyze the readings. In 2025, the data collected from the instrument should be compared with normal operating parameters. Sudden changes or irregularities in readings can indicate potential issues. For example, if a sensor shows an unexpected spike or a steady decline, further diagnosis is needed to pinpoint the cause.

2. Check Power Supply

Power supply failures are a common cause of instrument malfunctions. Before proceeding with more complex diagnostics, always ensure that the instrument is receiving the correct voltage and current levels. Additionally, verify that the power cables are correctly connected and not damaged.

3. Examine Connections and Cables

Ensuring that all connections and cables are properly secured and undamaged is a simple yet critical step. Loose or broken connections can disrupt instrument performance, causing readings to be inaccurate or erratic. Use a visual inspection and, if necessary, test the continuity of the cables using a multimeter.

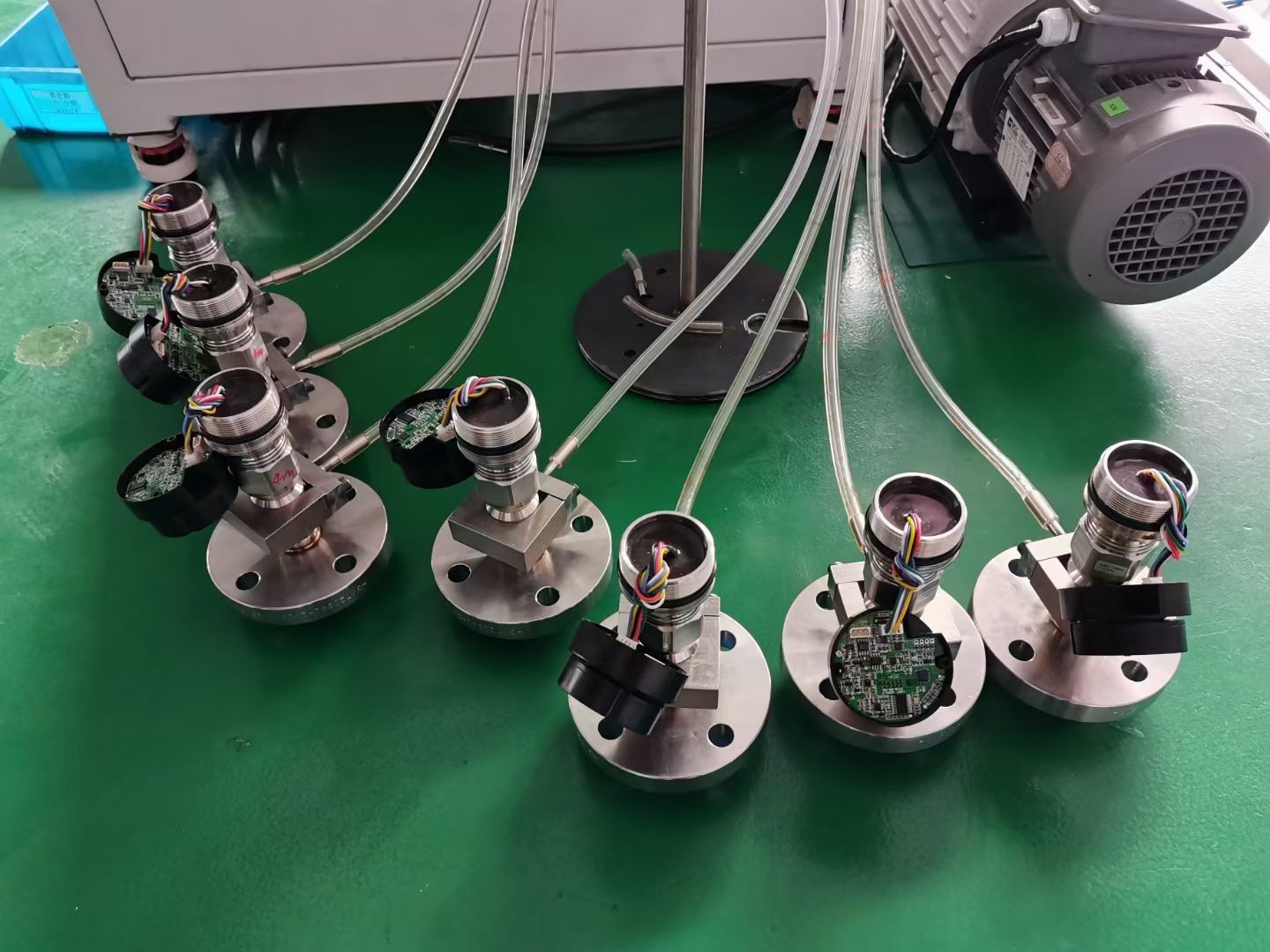

4. Calibrate the Instrument

Regular calibration is fundamental in verifying the accuracy of the instrument. Calibrating the instrument against a known standard can help identify any inaccuracies in the readings. This process involves adjusting the instrument to match the known values, ensuring that it is operating within the acceptable range.

5. Inspect Software and Firmware

In modern instruments, the software and firmware play a crucial role in the overall functionality. Check for any software updates or firmware upgrades that may have been released since the instrument was last updated. Outdated software or firmware can lead to malfunctions, so ensure that the instrument is running the latest version.

6. Conduct a Visual Inspection

A thorough visual inspection can often reveal the source of the problem. Look for any visible signs of damage, such as cracks, overheating components, or loose mounting screws. Pay attention to any unusual odors or sounds, as these can also indicate potential issues.

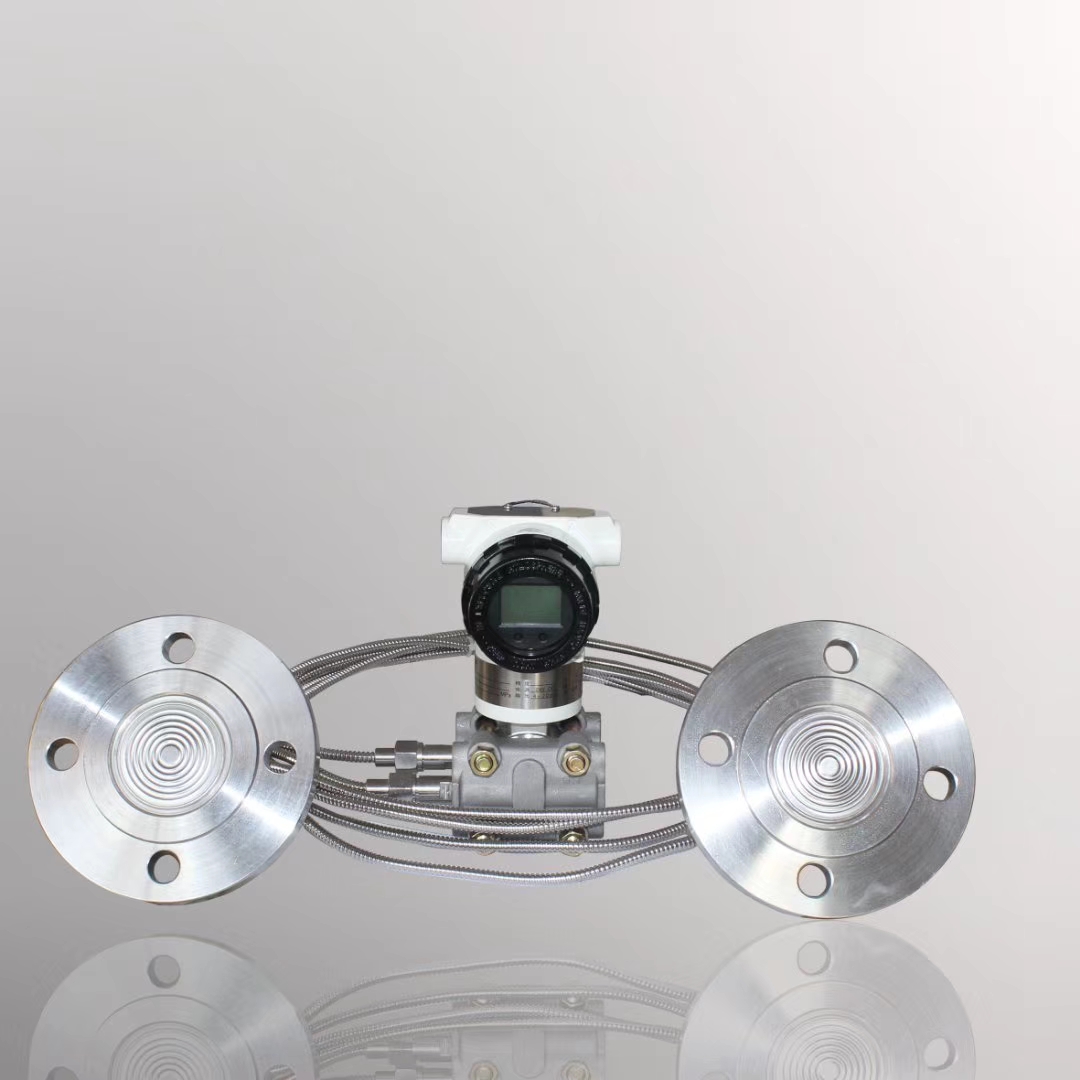

7. Conduct a Pressure or Water Test

For instruments that measure pressure or water levels, conducting a pressure or water test can help identify leaks or blockages. This involves applying a known pressure or introducing a known volume of water to the instrument and checking for any unexpected changes in readings or signs of leakage.

8. Perform a Resistor Check

Checking the resistor values within the instrument can help identify any electrical issues. Measure the resistance of key components with a multimeter and compare it with the manufacturer’s specifications. Resistor values that deviate from the norm may indicate a faulty component.

9. Use Diagnostic Tools

Modern diagnostic tools can provide detailed insights into the internal workings of an instrument. Utilize software diagnostic tools or specialized instruments designed to detect and pinpoint faults. These tools can often provide error codes or specific areas of concern that can guide further troubleshooting.

10. Consult the User Manual

The user manual is an invaluable resource for troubleshooting instrument faults. It contains detailed instructions and troubleshooting guides specific to the instrument model. Refer to the manual for guidance on common issues and the recommended diagnostic steps.

Conclusion

Maintaining the accuracy and reliability of instruments is essential for any industrial or scientific environment. By employing these essential diagnostic methods, maintenance technicians can accurately identify and resolve instrument faults. Regular calibration, power supply checks, and software updates are just a few of the methods that can help ensure that instruments continue to operate at their best.

By following these diagnostic methods, technicians can minimize downtime, reduce errors, and improve overall performance. In 2025, the use of these techniques will be increasingly important as technology continues to advance and systems become more complex.