Seven Suggestions for Instrument Maintenance and Upkeep to Extend Equipment Lifespan

In today’s fast-paced industrial and laboratory settings, maintaining the integrity and accuracy of instruments is critical. Whether you are measuring in a chemistry lab or calibrating sensors on industrial machinery, ensuring your instruments function correctly and last through multiple usage cycles can significantly impact productivity and accuracy. Here are some practical and expertly endorsed strategies to help you achieve this.

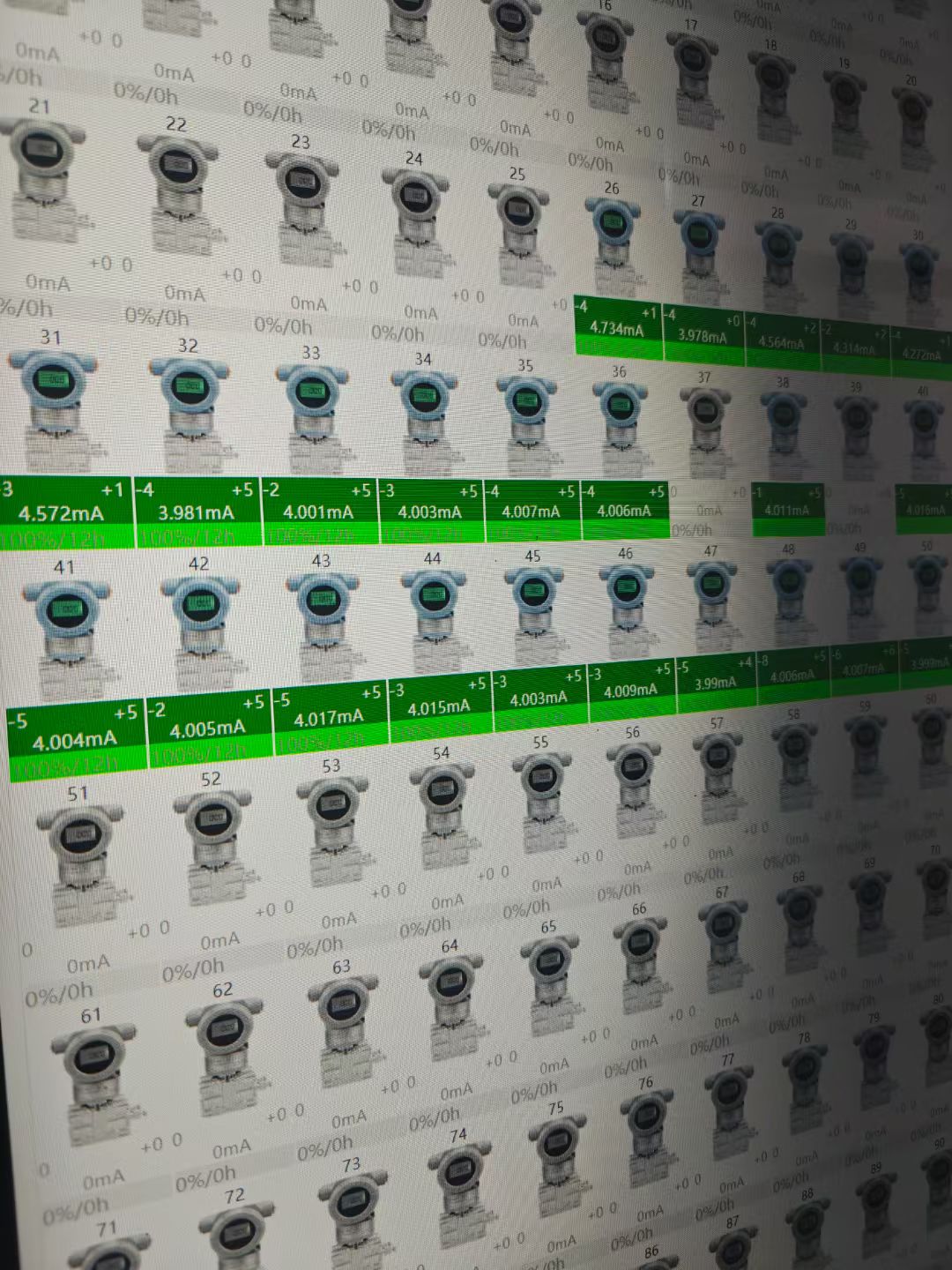

Regular Calibration and Testing

Regularly calibrating and testing your instruments is the first step in keeping them in top condition. Over time, instruments can drift from their initial calibration or experience wear and tear. By conducting periodic checks, you can catch any discrepancies early and address them before they become problematic. Keep a record of all calibration dates and results, as this will help you stay on top of your maintenance schedule. 2025

Clean and Organize

A clean environment for your instruments can prevent contamination and reduce the risk of unexpected failures. Dust, debris, and corrosive substances can damage instruments, affecting accuracy and functionality. Ensure your workspace is clean and organized. Regularly clean your instruments according to the manufacturer’s guidelines, especially after use. 2025

Proper Storage

Proper storage conditions are essential for prolonging the life of your instruments. Store them in a stable and controlled environment, free from extremes of temperature and humidity. This will also help prevent damage from physical shocks or vibrations. Consider using protective cases or bags to cushion and protect delicate components. 2025

Follow Manufacturer Guidelines

Each instrument comes with specific maintenance requirements outlined by the manufacturer. Adhering to these guidelines is crucial. These guidelines often include information on lubrication requirements, recommended cleaning protocols, and inspection points. Ignoring them can lead to premature failure. 2025

Regular Check-ups and Inspections

Beyond regular calibration, performing thorough check-ups and inspections is vital. Look for signs of wear and tear, such as cracks, loose connections, or deteriorating seals. Pay special attention to any components that are exposed to harsh environments or are prone to wear. Addressing these issues early can save you from costly repairs or replacements. 2025

Training and Documentation

Ensure that the personnel using your instruments are trained in proper handling and maintenance procedures. This will not only extend the lifespan of your instruments but also enhance overall safety and accuracy. Document all maintenance activities and make them accessible for future reference. This will also help in identifying trends and potential areas for improvement. 2025

Seek Manual Assistance

While instrument manufacturers provide guidelines, sometimes detailed instructions can be difficult to interpret. Utilize manuals and technical literature to gain a deeper understanding of the intricacies of your instruments. Online communities and forums can also be valuable resources where you can seek advice and share experiences with other users. 2025

Conclusion

By following these seven suggestions, you can significantly extend the lifespan of your instruments, ensuring they remain accurate and reliable. Regular maintenance and careful handling are key to achieving cost savings and enhancing the efficiency of your operations. Remember, the investment in maintenance today can pay off in the long run with fewer downtimes and greater productivity. 2025

These tips, combined with a proactive approach to instrument care, can help you maintain optimal performance and longevity of your equipment.