Development of Preventive Maintenance Plan: An Evolving Approach in 2025

Preventive maintenance plans have continued to evolve, demonstrating their resilience and adaptability in the face of dynamic technological advancements and changing industrial needs. In the context of 2025, the emphasis on leveraging predictive analytics has become more pronounced, transforming maintenance strategies from reactive to proactive. A key challenge facing industries today is ensuring that equipment remains in optimal condition through preventive measures that mitigate potential failures. This article delves into the development of preventive maintenance plans in light of 2025 trends, focusing on how these plans can be optimized to enhance operational efficiency and reduce downtime.

The Importance of Proactive Maintenance in 2025

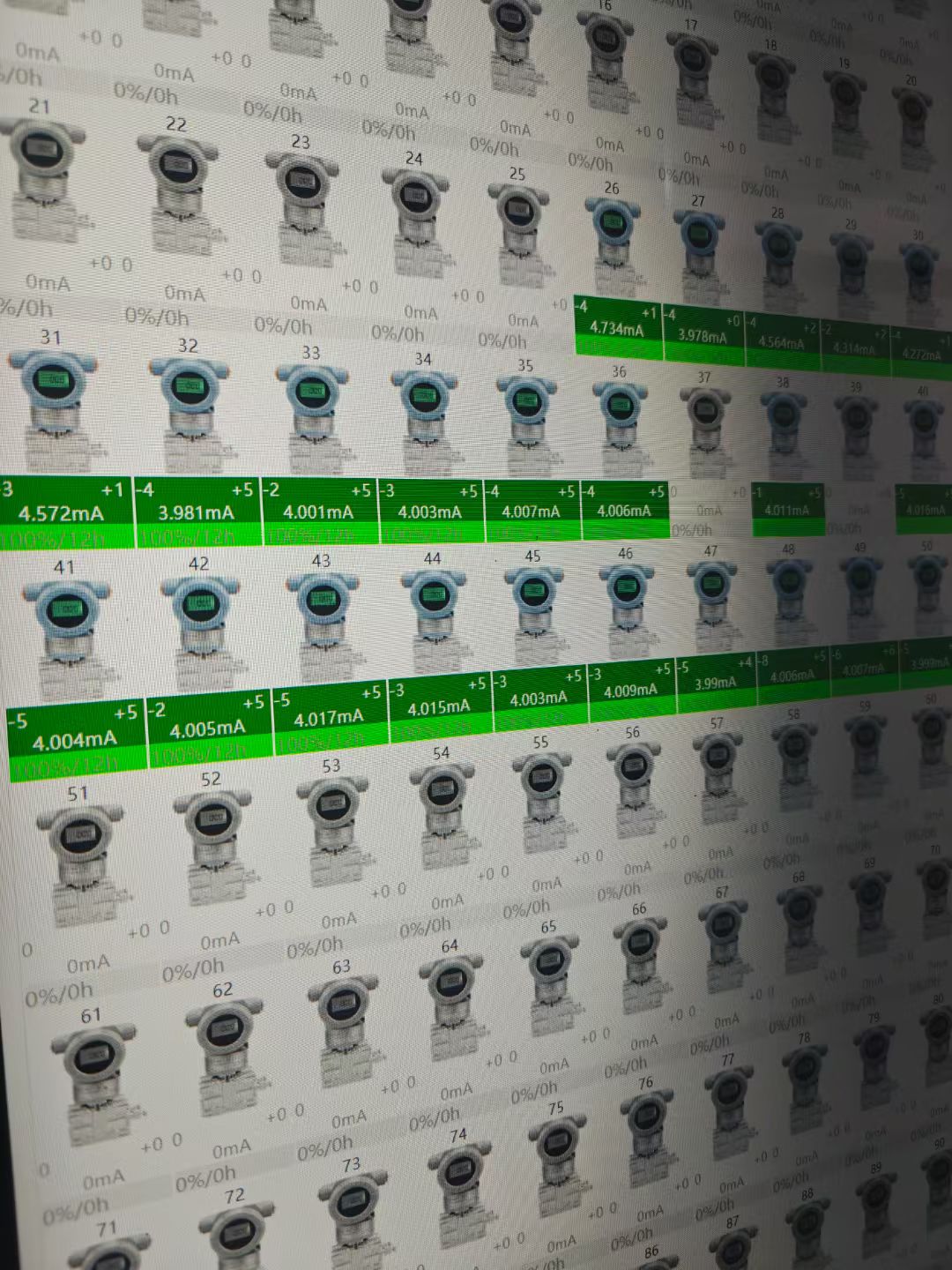

Industry 4.0 technologies, coupled with the Internet of Things (IoT), have introduced a new era of monitoring and maintenance. These technologies enable real-time data collection from machinery and equipment, allowing for continuous monitoring of performance metrics. By integrating predictive analytics, industries can forecast when maintenance will be necessary, thereby preventing sudden equipment failures and associated costs. As the world steps into 2025, the adoption of these technologies has become paramount, as even a minor equipment failure can lead to significant downtime, impacting productivity and profitability.

Issues with Traditional Maintenance Approaches

Conventional maintenance schedules often rely on time-based or condition-based methods. Time-based maintenance schedules are reactive, only addressing issues after a certain period has elapsed, while condition-based maintenance is slightly more proactive, relying on indicators such as wear and tear to schedule maintenance. Both approaches have inherent limitations; time-based maintenance can result in unnecessary repairs, while condition-based maintenance might not catch developing issues in a timely manner. In 2025, the focus is shifting towards a more sophisticated preventive maintenance strategy that combines the best of these methods—using real-time data and predictive analytics to ensure optimal performance.

Innovative Solutions for Preventive Maintenance Planning

To address these challenges, 2025 sees the rise of intelligent preventive maintenance plans. These plans integrate machine learning algorithms and predictive models to forecast maintenance needs with high accuracy. One of the key tools in this approach is the use of artificial predictors, which analyze historical data to identify patterns and predict future equipment behavior. Additionally, autonomous inspection procedures are being implemented, where drones and robots perform regular checks without requiring downtime, allowing for more frequent and thorough inspections.

For instance, a leading manufacturer in the automotive sector implemented an integrated predictive maintenance system. By leveraging IoT sensors and machine learning algorithms, they were able to predict and prevent potential failures in key components. The result was a 30% reduction in unscheduled maintenance downtime and a 25% improvement in overall equipment effectiveness (OEE).

Comparative Analysis with Traditional Methods

When comparing traditional maintenance strategies with these innovative approaches, the benefits become quite clear. Traditional methods were often costly and inefficient, leading to unnecessary maintenance actions and failing to catch developing issues. In contrast, the use of intelligent predictive maintenance plans leads to:

- Enhanced Predictive Accuracy: By using advanced analytics and IoT technologies, the accuracy of maintenance predictions is significantly improved.

- Reduced Downtime: Preventive measures ensure that equipment remains in optimal condition, minimizing the risk of sudden failures.

- Cost Efficiency: Valuable resources are used more effectively, reducing waste and increasing operational efficiency.

In practical scenarios, a company that migrated from a traditional reactive maintenance approach to a predictive model saw a 45% decrease in maintenance costs and a 50% reduction in overall equipment downtime. This shift not only improved operational reliability but also enhanced the company’s bottom line.

Conclusion

The development of preventive maintenance plans in 2025 marks a significant shift towards more intelligent and efficient maintenance strategies. By leveraging the latest technologies and data analytics, industries can achieve greater operational efficiency and reliability. The potential benefits of adopting these innovative approaches are clear, making it imperative for organizations to revisit their maintenance plans and adopt more proactive strategies. As the landscape of industrial maintenance continues to evolve, the adoption of predictive maintenance will become increasingly critical, and those who embrace these changes will stand to gain significant advantages.