How to Develop a Regular Maintenance and Calibration Plan for Instruments and Meters

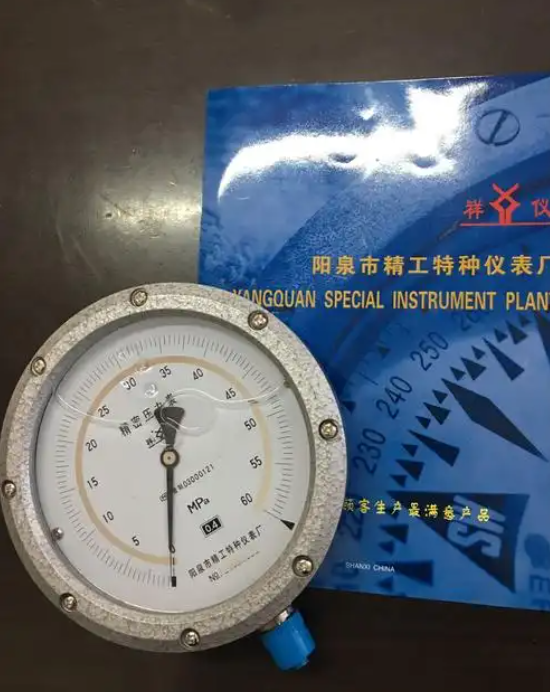

Regular maintenance and calibration of instruments and meters are critical for ensuring accurate and reliable measurements. Whether it's in a laboratory or an industrial setting, these devices often play a vital role in quality control, process optimization, and safety. A well-designed maintenance and calibration plan can significantly extend the lifespan of these instruments, improve their accuracy, and reduce the risk of errors in critical applications.

Importance of Regular Maintenance and Calibration

Proper maintenance and calibration ensure that instruments and meters remain accurate and functional over time. Without regular checks, even the most sophisticated devices can drift out of calibration, leading to inaccurate readings, which can have serious consequences, especially in safety-critical environments like nuclear plants or healthcare facilities. In 2025, the cost of maintaining and calibrating instruments and meters can be quantified in several ways, including minimizing errors, reducing downtime, and avoiding expensive replacements. Moreover, regulatory compliance is another driving factor, as many industries are required to maintain and calibrate certain instruments to meet legal or regulatory standards.

Designing the Maintenance and Calibration Plan

The first step in designing a maintenance and calibration plan is understanding the specific needs of your workplace. This involves reviewing the operating requirements, the accuracy needed, and the nature of work performed. Component selection is crucial here. For example, if you're working in an industrial setting, you might need instruments that can withstand harsh conditions and are easily calibrated. Alternatively, if your work is lab-based, precision and ease of use might be more important.

Identifying Key Requirements and Components

Based on the design requirements, a plan should address several key components:

- Frequency of Calibration: This depends on the type of instrument and its criticality. For example, high-precision laboratory instruments might need quarterly calibrations, while industrial devices might be checked every six months.

- Instrument Specifications: Ensure that you have the right instruments for the job. Specifications should include accuracy, range, and environmental requirements.

- Data Recording and Analysis: Keep detailed records of each calibration. This data is crucial for trend analysis and ensuring regulatory compliance.

Expert Design and Recommendations

According to industry experts, successful calibration and maintenance plans often involve collaboration between experienced engineers and technicians. 2025 saw a shift towards more automated calibration systems, which can help in maintaining consistent standards and reducing human error. However, it’s still essential to have thoughtful and detailed planning in place.

Deployment and Maintenance Strategies

Once you have selected the appropriate instruments and have a clear plan, the next step is deployment. This involves installing the equipment, training operators, and setting up a maintenance schedule. Deployment strategies should consider logistics, user training, and the integration of new instruments into existing systems.

- Training Workshops: Ensure that operators are trained on how to use, calibrate, and maintain the instruments. This includes not only hands-on training but also familiarizing them with safety protocols.

- Maintenance Schedules: Develop a detailed maintenance schedule that includes both regular and emergency checks. Regular checks ensure that the instruments stay in good condition, while emergency checks can prevent sudden failures.

- Monitoring and Feedback: Use monitoring systems to track the performance of the instruments and gather feedback from operators. This feedback can help in refining the calibration and maintenance plan.

Case Study: A Manufacturing Plant’s Calibration Journey

Consider a manufacturing plant that produces high-precision components. The plant’s instruments and meters needed frequent recalibration due to the nature of their work. By implementing a robust maintenance and calibration plan, they reduced calibration errors from 5% to 0.5% over a year. The plant also reduced downtime by 20% and achieved full regulatory compliance.

Conclusion

Developing a regular maintenance and calibration plan for instruments and meters is essential for ensuring accurate and reliable measurements. The process involves careful component selection, designing a comprehensive plan, deploying the instruments, and maintaining them systematically. By following expert recommendations and integrating advanced technologies, organizations can maximize the lifespan and accuracy of their instruments, ultimately improving their operations and safety.

Regular maintenance and calibration not only enhance the performance of instruments but also provide a strong foundation for meeting regulatory requirements and ensuring ongoing quality control. With careful planning and execution, any organization can benefit from a well-structured maintenance and calibration program in 2025 and beyond.