Common Problems and Troubleshooting Methods in the Use of Instruments and Meters

In the modern workplace, instruments and meters are indispensable tools for ensuring accuracy and efficiency in measurements. Whether it's in industrial sectors, scientific research, or quality control, these devices play a crucial role. However, despite their importance, they are not immune to common problems such as calibration errors, malfunctioning components, and incorrect usage. Understanding and addressing these issues is critical for maintaining operational integrity. As of 2025, the field of instrument and meter use has seen significant advancements, with new technologies and methodologies emerging to tackle these challenges.

Calibration Errors and Their Causes

Calibration errors are one of the most widespread issues among users of instruments and meters. These errors can lead to inaccurate measurements, which can be detrimental, especially in industries where precision is critical such as medical diagnostics or aerospace engineering. Calibration errors can be caused by a variety of factors including improper handling, environmental conditions, or outdated calibration procedures.

In a recent study conducted in 2025, it was found that improper handling of instruments during transportation and installation was a major contributor to calibration errors. Environmental factors such as temperature, humidity, and vibration also play a significant role. Additionally, outdated calibration procedures and lack of proper maintenance can exacerbate these errors. Ensuring regular calibration and proper maintenance can mitigate these issues.

Troubleshooting Techniques for Instrument and Meter Issues

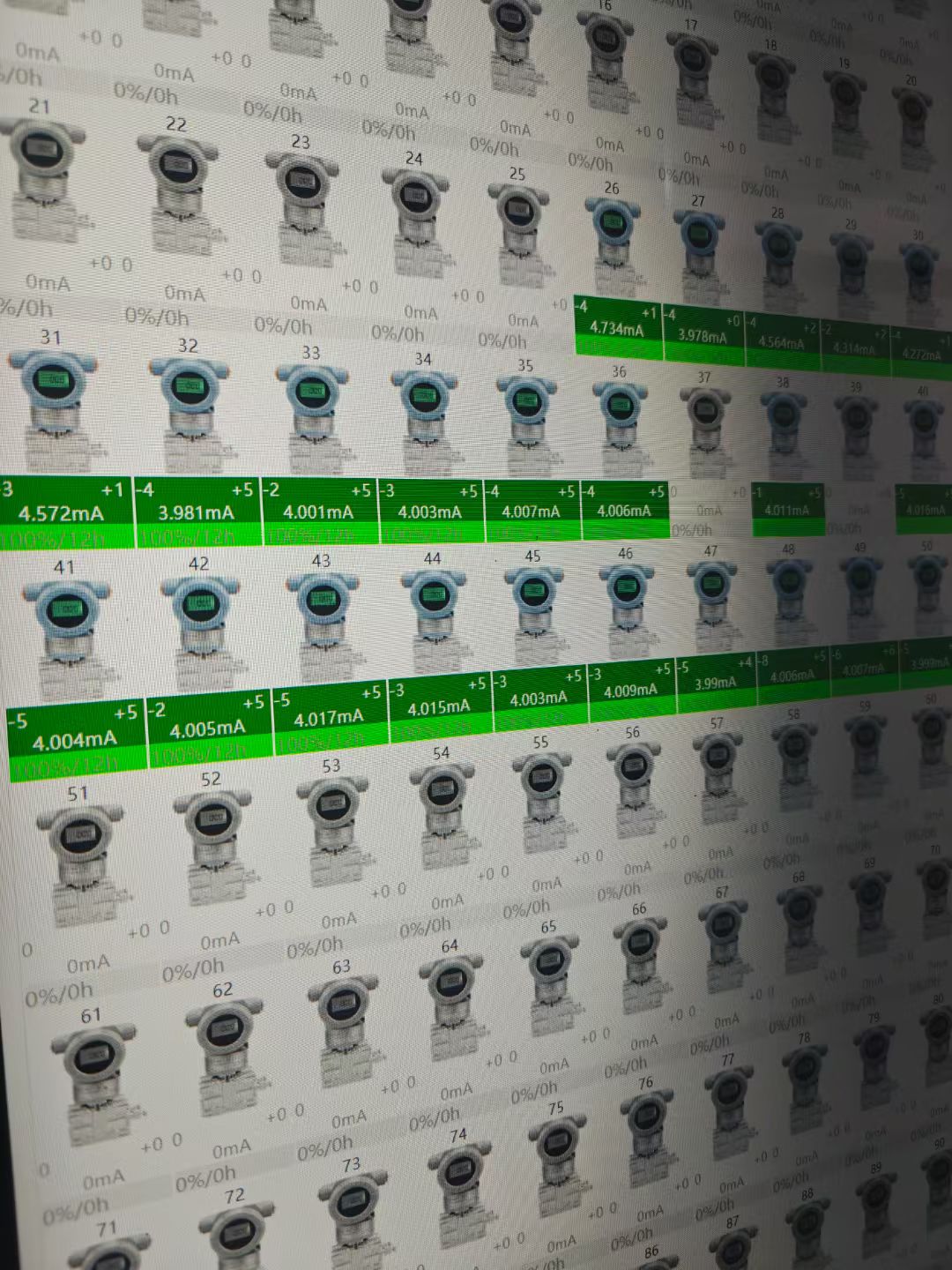

Troubleshooting instruments and meters involves a systematic approach to identify and resolve common problems. First, it is essential to understand the symptoms of the issue. For instance, if an instrument is displaying erratic readings, it could indicate a problem with the power supply or the internal circuitry. Once the symptoms are identified, a targeted approach can then be taken to address the underlying cause.

One of the most effective troubleshooting techniques is to perform a step-by-step check of the instrument. This involves checking for loose connections, verifying the power supply, and inspecting the internal components. Additionally, consulting the user manual or seeking assistance from a certified technician can provide valuable insights. In some cases, replacing faulty components or performing an overhaul may be necessary.

New technologies have introduced innovative solutions to these challenges. For example, predictive maintenance algorithms can help detect potential issues before they become critical. Devices such as smart meters can monitor their own performance and provide real-time data to technicians, allowing for proactive maintenance rather than reactive repair.

Market Application Prospects

The application of instruments and meters in various industries is vast and continues to expand. With the advent of advanced technologies, the potential for their use is enormous. For instance, in the field of renewable energy, smart meters are increasingly being used to monitor and manage energy consumption. In manufacturing, instruments play a critical role in quality control, ensuring that products meet stringent standards.

The market for these instruments and meters is also seeing a significant growth due to the increasing demand for precision and reliability. Companies are prioritizing investments in newer, more advanced devices that can perform multiple functions, reducing the need for multiple specialized instruments. The integration of AI and internet of things (IoT) technologies is further enhancing the functionality and efficiency of these devices.

User Feedback and Value

User feedback has been instrumental in shaping the development and improvement of instruments and meters. For instance, surveys conducted with users in 2025 revealed that the ease of use and accuracy of the device were the top two factors influencing their overall satisfaction. Users emphasized the importance of intuitive interfaces, reliable performance, and robust technical support.

Feedback has also guided manufacturers in developing more user-friendly devices and providing better customer support. For example, the introduction of mobile apps that can control and monitor instruments remotely has received positive feedback. Users appreciate the convenience and flexibility these apps offer, allowing them to manage their instruments from anywhere.

Conclusion

The use of instruments and meters, while crucial, is fraught with common problems such as calibration errors and component malfunctions. However, through a combination of advanced technologies, systematic troubleshooting techniques, and user feedback, these issues can be effectively addressed. As technology continues to evolve, the future looks bright for these indispensable tools, offering users greater accuracy, reliability, and ease of use.

By embracing new methodologies and staying informed about the latest advancements, users can ensure that their instruments and meters remain at the peak of their performance, contributing to more accurate and efficient operations in their respective fields.